Goldstar America

954.305.8490

www.goldstarprinters.com

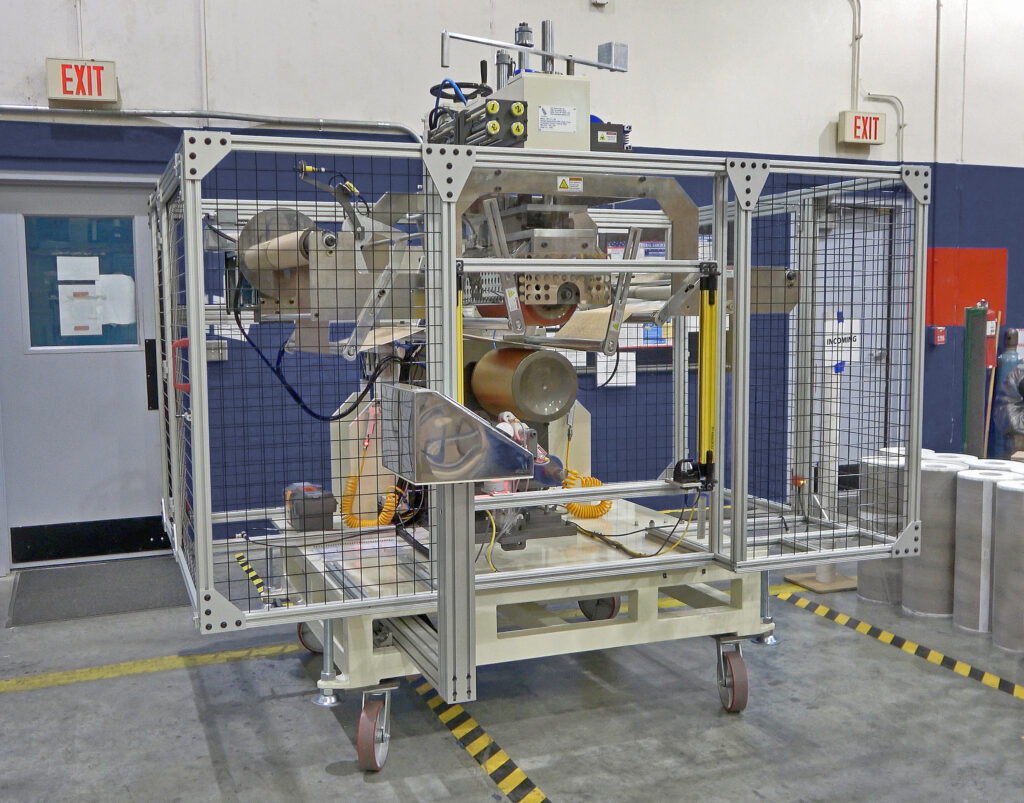

Goldstar America, Twinsburg, Ohio, has introduced the C-350, an automatic thermal transfer labeling machine engineered for efficiency and precision. Designed to accommodate cylindrical and conical containers ranging from one to 20 liters, the C-350 offers full automation with loading and unloading capabilities. Key features include a four-station indexer with brake motor for accurate positioning and a PLC-based system with HMI interface and vertical foil movement for precise label application. The machine achieves speeds of up to 800 containers per hour for 4-liter sizes, enhancing productivity for businesses seeking reliable labeling solutions.

AutoTran, Inc.

239.659.2515

www.autotran.net

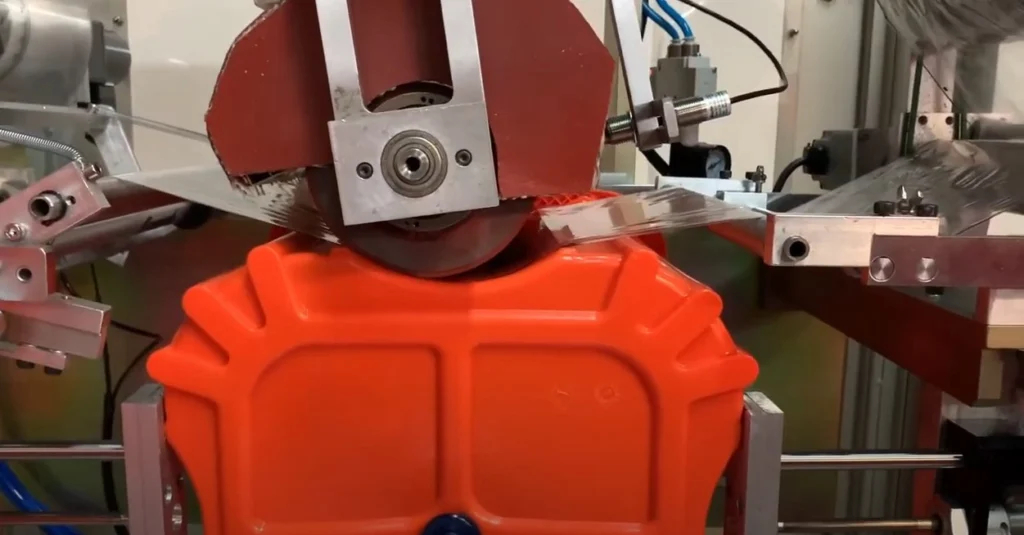

AutoTran, Inc., Naples, Florida, has introduced the AutoTransfer 6.0. The AutoTransfer 6.0 is a hybrid of a pad printer blended with heat transfer technology. Utilizing the features of a printing pad, the AutoTransfer 6.0 is able to apply heat transfers to an extensive number of shapes in one compression. The capabilities allow for transferring full-color artworks onto substrates that would be restricted by inkjet equipment, making it much more economical and time-saving than a four-color pad printing process.

CPS Resources, Inc.

704.628.7678

www.cpsresources.com

CPS Resources, Inc., Indian Trail, North Carolina, offers customized hot stamp equipment and foil film solutions to fit the specific manufacturing needs of its customers. CPS Resources’ specialized pivot hot stamp machine is ideal for decorating tapered molded plastic goods. The company also provides custom-engineered vertical stamping and roll-on equipment for inline extrusion as well as offline applications. As a full-service solutions provider, the company offers foil films, rollers, stamping dies, automation and engineering services.

Hot Stamp Supply Company

877.343.4321

www.hotstampsupply.com

Hot Stamp Supply Company, in Winchester, Virginia, offers the Bag Master, which was originally designed to meet the needs of the high-fashion leather products industry. Typically, these customers need a large adjustable work area with easy and open access to position, locate and stamp their products. The Bag Master’s print head has vertical adjustments up to 9″ high, making it a perfect choice for placing monograms or names on purses, handbags, clutches, leather products, tall products, wide, or odd-shaped goods with tops, flaps, zippers or folds.

Koenig & Bauer

978.463.0050

www.kammann.de

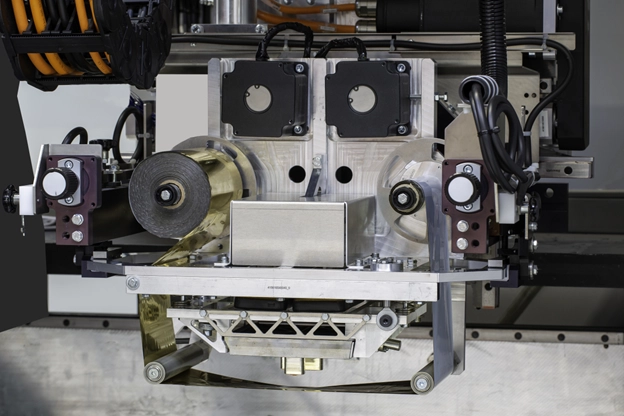

Koenig & Bauer Kammann, Portsmouth, New Hampshire, has developed the K29 Mobile Hot Stamping Module, which can be inserted into an existing Kammann K15CNC standard screen holder and is suitable for hot stamping small images with cliché tooling using the flat roll process. The installation and removal of the K29 Mobile Hot Stamping unit is easy, efficient and takes less than 15 minutes. The cliché angles can be adjusted to ensure pressure is applied in the proper areas. The hot stamping area is up to 100 mm x 100 mm. The K29 can be used to hot stamp round and oval articles.

North Pacific International, Inc.

909.628.2224

www.npifoil.com

The heat transfer label and hot stamping machine from North Pacific International, Inc., in Chino, California, offers a turnkey solution for any plastic decoration project. The heat transfer label, combined with the hot stamping machine, provides a cost-efficient and effective solution for molders for their hard-to-decorate irregular shaped molds. The heat transfer label and hot stamping machine will not leave any wrinkles and bubbles upon hot stamping, and it offers resistance to many environments to maintain the decoration throughout the lifespan of the product.

OMSO North America, Inc.

859.282.6676

www.omso.it

OMSO, Erlanger, Kentucky, an Italian manufacturer of machines for direct decoration of primary packaging, has developed an integrated station for hot stamping on plastic containers of various shapes and sizes for the Servobottle screen printing machine. The new hot stamping station allows the two technologies to be combined in one process. This saves space, optimizes time and ensures perfect color and decoration register accuracy. This technique particularly is popular in the cosmetics and luxury packaging sector, as it allows for impressive metallic, matte or glossy effects. Equipped with a linear camera quality control system, Servobottle ensures zero-defect production, offering flawless decorations for cosmetic and luxury packaging.