Central Decal

800.869.7654

www.centraldecal.com

Central Decal, located in Burr Ridge, Illinois, is an in-mold decorating specialist. The first and second surface IMLs deliver the quality, aesthetics and performance required for a wide range of applications. What makes the company’s IMLs unique is the repeatability of debris free IMLs. Central Decal’s proprietary technology creates a permanent bond between the IML and a similar or dissimilar resin, eliminating delamination, popping or bubbling between the IML and resin. IMLs are provided with smooth or textured surfaces and gloss or matte finishes. As for inks – Central Decal prints mirror chrome, brushed stainless, dead-front windows, display windows, metallics, patterns and fades.

Central Decal, located in Burr Ridge, Illinois, is an in-mold decorating specialist. The first and second surface IMLs deliver the quality, aesthetics and performance required for a wide range of applications. What makes the company’s IMLs unique is the repeatability of debris free IMLs. Central Decal’s proprietary technology creates a permanent bond between the IML and a similar or dissimilar resin, eliminating delamination, popping or bubbling between the IML and resin. IMLs are provided with smooth or textured surfaces and gloss or matte finishes. As for inks – Central Decal prints mirror chrome, brushed stainless, dead-front windows, display windows, metallics, patterns and fades.

DuraTech Industries

608.781.2570

www.duratech.com

Duratech, headquartered in La Crosse, Wisconsin, is introducing a new era of efficient warmth with its IMD printed heaters which combine sleek design with innovative technology to provide a reliable, energy-saving heat source. Printed heaters are finding their way into IMD applications in a variety of industries, including healthcare, automotive, appliance and consumer electronics. The applications benefiting from IMD printed heaters are – when conventional heating methods are too costly; when the weight and thickness are an issue with traditional heating methods; when conforming the heater to a custom shape is important; and when sustainability is a concern.

Duratech, headquartered in La Crosse, Wisconsin, is introducing a new era of efficient warmth with its IMD printed heaters which combine sleek design with innovative technology to provide a reliable, energy-saving heat source. Printed heaters are finding their way into IMD applications in a variety of industries, including healthcare, automotive, appliance and consumer electronics. The applications benefiting from IMD printed heaters are – when conventional heating methods are too costly; when the weight and thickness are an issue with traditional heating methods; when conforming the heater to a custom shape is important; and when sustainability is a concern.

InkWorks Printing

920.827.4374

www.inkworks.com

InkWorks Printing, based in Plymouth, Wisconsin, is a technology-focused label printing company that specializes in solutions for in-mold decoration and other product labeling and packaging solutions. InkWorks has a robust offering of IML solutions for PP, PE, ABS and PC resins. Its laminating technology can create solutions that offer tactile surfaces, anti-microbial functionality or metallic appearance. Digital imaging allows for quality image reproduction as well as the ability to focus on market segments with targeted solutions.

Krevera

617.417.1919

www.krevera.com

Krevera, located in Boston, Massachusetts, specializes in automated defect detection and reduction in plastic injection molding, with a focus on IMLs. The company’s technology detects even the most challenging label defects – such as contamination, label rotation, label folds, blisters and more – providing detailed insights into the type, size and location of each defect. Krevera integrates this data with the customer’s IMM and any connected robotics to perform causal analysis. Leveraging this information, the company enables root cause analysis, processes drift detection and provides preventative maintenance. Join Krevera in revolutionizing plastic injection molding by replacing art with data and analysis.

Krevera, located in Boston, Massachusetts, specializes in automated defect detection and reduction in plastic injection molding, with a focus on IMLs. The company’s technology detects even the most challenging label defects – such as contamination, label rotation, label folds, blisters and more – providing detailed insights into the type, size and location of each defect. Krevera integrates this data with the customer’s IMM and any connected robotics to perform causal analysis. Leveraging this information, the company enables root cause analysis, processes drift detection and provides preventative maintenance. Join Krevera in revolutionizing plastic injection molding by replacing art with data and analysis.

KURZ

704.927.3700

www.kurzusa.com

The limitations between the environment and design concepts are being replaced by innovation. Function and operability can be concealed behind a Shy Tech design that comes alive and shows its brilliance with touch and movement. KURZ offers design and intelligence of the surface in one step, which produces no limits to the look, feel and functionality of the product, including haptic, natural and backlit effects.

MCC Verstraete US

608.438.8820

iml.mcclabel.com

MCC Verstraete US, headquartered in Batavia, Ohio, has more than 55 years of experience in printing labels for injection molding, blow molding and thermoforming. Its products are 100% made in the US. In-depth understanding of materials, innovation and sustainability, has made MCC Verstraete a world market leader, producing over 80 million in mold labels every single day for numerous segments within the packaging industry.

MCC Verstraete US, headquartered in Batavia, Ohio, has more than 55 years of experience in printing labels for injection molding, blow molding and thermoforming. Its products are 100% made in the US. In-depth understanding of materials, innovation and sustainability, has made MCC Verstraete a world market leader, producing over 80 million in mold labels every single day for numerous segments within the packaging industry.

Nazdar

913.422.2255

www.nazdar.com

With the company based in Shawnee, Kansas, Nazdar’s 8400 Series Screen Ink is a polyester solvent-based/conventional screen ink which meets the requirements of various industrial and specialty print applications including the insert mold decorating (IMD) process. The dried ink film exhibits good gloss and flexibility for forming, post-form trimming, resistance to wash out during the molding process and adhesion to polycarbonate injection mold resin. Overprinting the 8400 with the 8449 Tie-Coat screen ink promotes adhesion to injection resins other than polycarbonate (PC), such as ABS, PMMA and PVC. The addition of NB72 Catalyst or NB80 Adhesion Promoter is necessary for in-mold decorating applications.

With the company based in Shawnee, Kansas, Nazdar’s 8400 Series Screen Ink is a polyester solvent-based/conventional screen ink which meets the requirements of various industrial and specialty print applications including the insert mold decorating (IMD) process. The dried ink film exhibits good gloss and flexibility for forming, post-form trimming, resistance to wash out during the molding process and adhesion to polycarbonate injection mold resin. Overprinting the 8400 with the 8449 Tie-Coat screen ink promotes adhesion to injection resins other than polycarbonate (PC), such as ABS, PMMA and PVC. The addition of NB72 Catalyst or NB80 Adhesion Promoter is necessary for in-mold decorating applications.

North Pacific International, Inc

909.628.2224

www.npifoil.com

Ontario, California-based North Pacific International (NPI) offers films for automotive interiors, exteriors, appliances and other industries. These films provide a variety of effects, including partial metallic finishes and high-resolution gravure printing. The automotive exterior foil is specially designed to eliminate the need for over-coating, making it ideal for demanding applications. NPI’s Roll-to-Roll solution also streamlines production by removing the pre-forming, die-cutting and loading steps required by traditional in-mold labeling (IML) with insert film. This efficient process reduces complexity and achieves cost savings by lowering printing costs per image.

Ontario, California-based North Pacific International (NPI) offers films for automotive interiors, exteriors, appliances and other industries. These films provide a variety of effects, including partial metallic finishes and high-resolution gravure printing. The automotive exterior foil is specially designed to eliminate the need for over-coating, making it ideal for demanding applications. NPI’s Roll-to-Roll solution also streamlines production by removing the pre-forming, die-cutting and loading steps required by traditional in-mold labeling (IML) with insert film. This efficient process reduces complexity and achieves cost savings by lowering printing costs per image.

Proell, Inc.

630.587.2300

www.proell.us/en-us

Proell, Inc., with its US subsidiary in St. Charles, Illinois, introduces its NORIPHAN® HTR N 990/011 NC, a specialized non-conductive deep black opaque ink designed for IMD/FIM applications. NORIPHAN® HTR N is an established, formable, back moldable, solvent-based, one-component screen printing ink for the film insert molding technology. This carbon black-free, non-conductive black is suitable for decorative prints, multi-layer printing and printing electronic applications such as backing metallic and polymer conductive pastes, without compromising functionality. The color shade has a high optical density, an electrical resistance in the giga ohm range, and is radar transmissible.

Proell, Inc., with its US subsidiary in St. Charles, Illinois, introduces its NORIPHAN® HTR N 990/011 NC, a specialized non-conductive deep black opaque ink designed for IMD/FIM applications. NORIPHAN® HTR N is an established, formable, back moldable, solvent-based, one-component screen printing ink for the film insert molding technology. This carbon black-free, non-conductive black is suitable for decorative prints, multi-layer printing and printing electronic applications such as backing metallic and polymer conductive pastes, without compromising functionality. The color shade has a high optical density, an electrical resistance in the giga ohm range, and is radar transmissible.

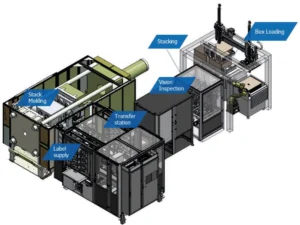

StackTeck

888.700.8555

www.stackteck.com

With decades of plastics industry experience, StackTeck, with headquarters in Brampton, Canada, provides a one stop shop from part design to a seamless fully integrated solutions provider for mold and automation production needs. StackTeck offers In Mold Labeling (IML) technology, high speed custom takeout automation, six axis robots for single face and stack molds with high-speed vision inspection for quality control including case packing and tray loading technology. The company’s mold centric automation features include quick product change for flexible automation solutions based on standardized modules and best in class componentry, for the smart factories of tomorrow.

With decades of plastics industry experience, StackTeck, with headquarters in Brampton, Canada, provides a one stop shop from part design to a seamless fully integrated solutions provider for mold and automation production needs. StackTeck offers In Mold Labeling (IML) technology, high speed custom takeout automation, six axis robots for single face and stack molds with high-speed vision inspection for quality control including case packing and tray loading technology. The company’s mold centric automation features include quick product change for flexible automation solutions based on standardized modules and best in class componentry, for the smart factories of tomorrow.