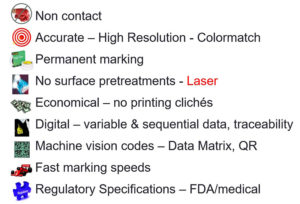

Noncontact digital processes, such as inkjet printing and laser marking on plastics, are modern technologies that offer numerous advantages compared to analog process, e.g., pad and screen printing. Digital processes are cost-effective and allow for decorating and printing of fully assembled products at the end of operations, resulting in better inventory management.

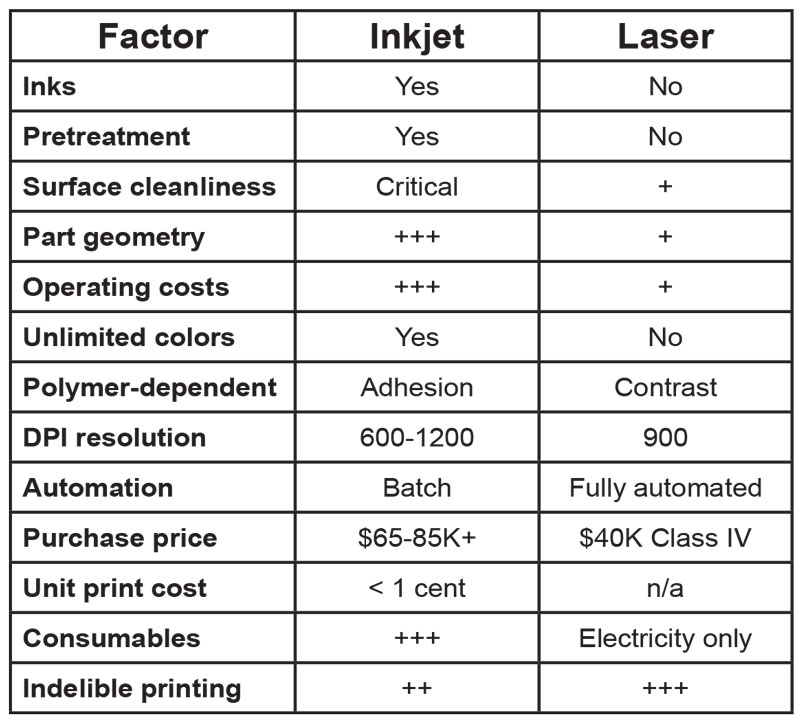

One example is laser marking of ABS computer keyboards in which fully assembled 101-piece keyboards are marked in less than 12 seconds, in any world language. Blank keyboards are pulled from inventory on-demand. Historically, pre-forecasted quantities of keyboards were pad printed (by language), boxed and inventoried for later shipment. This consumed a lot of warehouse storage space, inventory cost and labor. Drop-on-demand (DOD) inkjet and Ytterbium fiber laser processes are ideal for printing and marking products and mass customization by unique identification, serialization, barcode/2D codes, logos/graphics and more. The decision to utilize inkjet or laser on a given application can be complex depending upon the number of variables. This article examines the selection of thermoplastics, which is critical to achieve robust inkjet and laser marking results.

Inkjet printing and laser marking processes require precise engineering of ink/laser chemistries, thermoplastics, polymeric surface science, process/equipment design and skilled manufacturing techniques. Too often, companies choose to purchase off-the-shelf generic inks and equipment that fail to produce the required results. Manufacturers recognize the value of offering both technologies to meet custom printing requirements on diverse polymeric substrates.

Thermoplastics

Arguably, the most significant factor influencing the decision of which digital process to use is the polymer substrate. For inkjet printing, adhesion is critical. Variables affecting adhesion include polymer material (including colorants, fillers and additives), molding process, surface conditions, texture, and storage and handling. For laser marking, contrast relative to the substrate color is critical; although, in some applications low-level contrast is desired. Whichever process will be utilized, it’s important for design and manufacturing engineers to select the optimal thermoplastic that achieves field performance criteria and is easily printed or marked. Protective clear coatings (topcoat) allow extended chemical/abrasion resistant protection such as hot water dishwasher cleaning (exceeding 500 consecutive cycles). These coatings are applied on top of pigmented inks in either inkjet fluid or spray atomization.

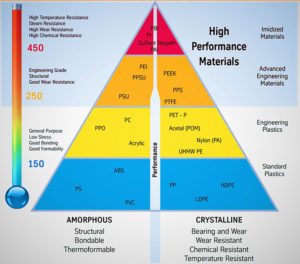

Thermoplastics are divided into two subcategories, amorphous and crystalline. The very long, chain-like molecules are held together by relatively weak Vander Waals forces. Generally, amorphous polymers possess better adhesion properties than crystalline. The term amorphous means to have no defined shape, or an easily altered shape. Crystalline implies that there is a regular, defined pattern to the molecular aggregates. Amorphous resins, such as ABS, styrene and polycarbonate, exhibit random, spaghetti-like structure. As heat is applied, they soften and do not have a sharply defined melting temperature.

Crystalline resins – such as polyolefins, PET and nylon – have orderly patterns, like a coiled spring. Just as a metal spring dampens vibration, so do crystalline materials. They have well defined melting temperature. In a polymer, these two states coexist, with adjacent sections of polymers packing into tight crystalline bundles held together by secondary attraction forces while other sections of the same molecules are unable to physically move into the crystalline lattice and remain amorphous (see Figure 2).

Selection of thermoplastics – process compatibility

For inkjet printing to be successful, the elevated temperature ink must easily jet from the printhead, appropriately interact with substrate and achieve strong adhesion. This intimate contact is termed “wetting” or “wetting out” the surface and refers to the ink’s ability to spread over the surface. However, most polymer surfaces are naturally hydrophobic and resist being wetted.

Characteristically, these plastics are chemically inert, nonporous surfaces with low surface energy, which makes printing adhesion nearly impossible. Surface energy is the excess energy that exists at the surface (as opposed to the bulk) of a solid.

Primary molding processing is critical to achieving the stated properties of the polymer material. Incorporating the proper plasma surface pretreatment in conjunction with surface texture and good manufacturing practices will resolve most, if not all, adhesion and wetting problems. Selecting the best thermoplastic for any given application is not easy. Part designers often seek chemical bulk material and surface properties that are often very difficult to print.

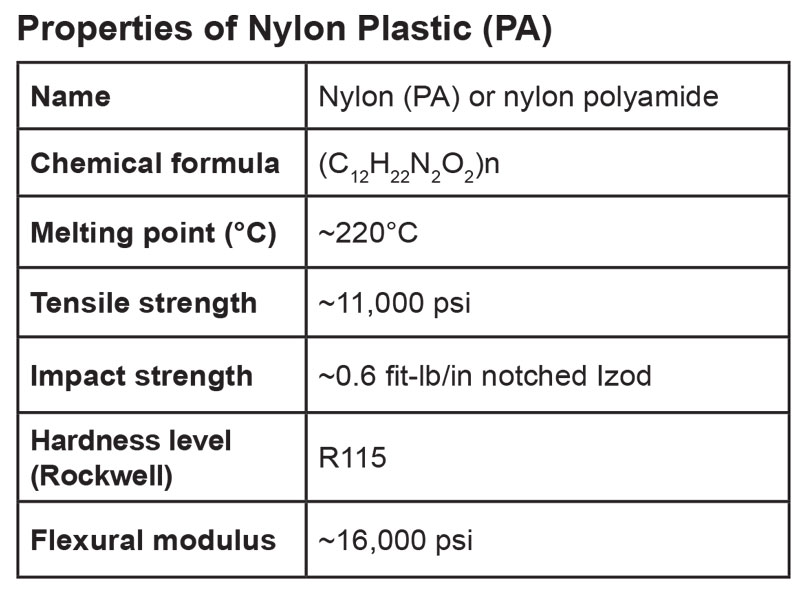

Color inkjet printing and laser marking on polyamide (nylon) is one of the most sought-after applications. The chemical composition of nylon gives it a high melting point, making it an excellent alternative to metal components in high-temperature environments, like car engines and other types of high-friction machinery. Like other thermoplastic materials, nylon plastic turns to liquid at its melting point rather than burning, meaning it can be melted down and remolded or recycled. Nylon material also doesn’t heat up easily when used in high-friction applications. However, inkjet inks do not adhere readily to nylon (or most low surface energy polymers) without specialized ink and pretreatment. This is due in part to its hydrophobic properties (see Figure 3).

First and foremost, ensure that nylon materials are properly dried and processed to achieve dry-as-molded properties. Resin manufacturers chemically produce their products differently, which can affect adhesion performance. Evaluate alternative suppliers by resin/grade and note the differences between Nylon 6, Nylon 66 (Nylon 11 and 12). Unlike Nylon 6, Nylon 66 is composed of two monomers, Hexamethylenediamine and adipic acid, each providing six carbon atoms – hence the 66 name. The material is more crystalline in nature than Nylon 6, which improves stiffness and tensile and flexural modulus. Nylon 6 will absorb slightly more moisture than Nylon 66. Following molding before secondary operations, products should be packed, preferably in polyester bags and not polybags. Low-molecular weight species found in polybags migrate to the surface, causing cross-contamination issues. Length of time in storage and temperature also affect adhesion performance. Print as soon as possible after molding.

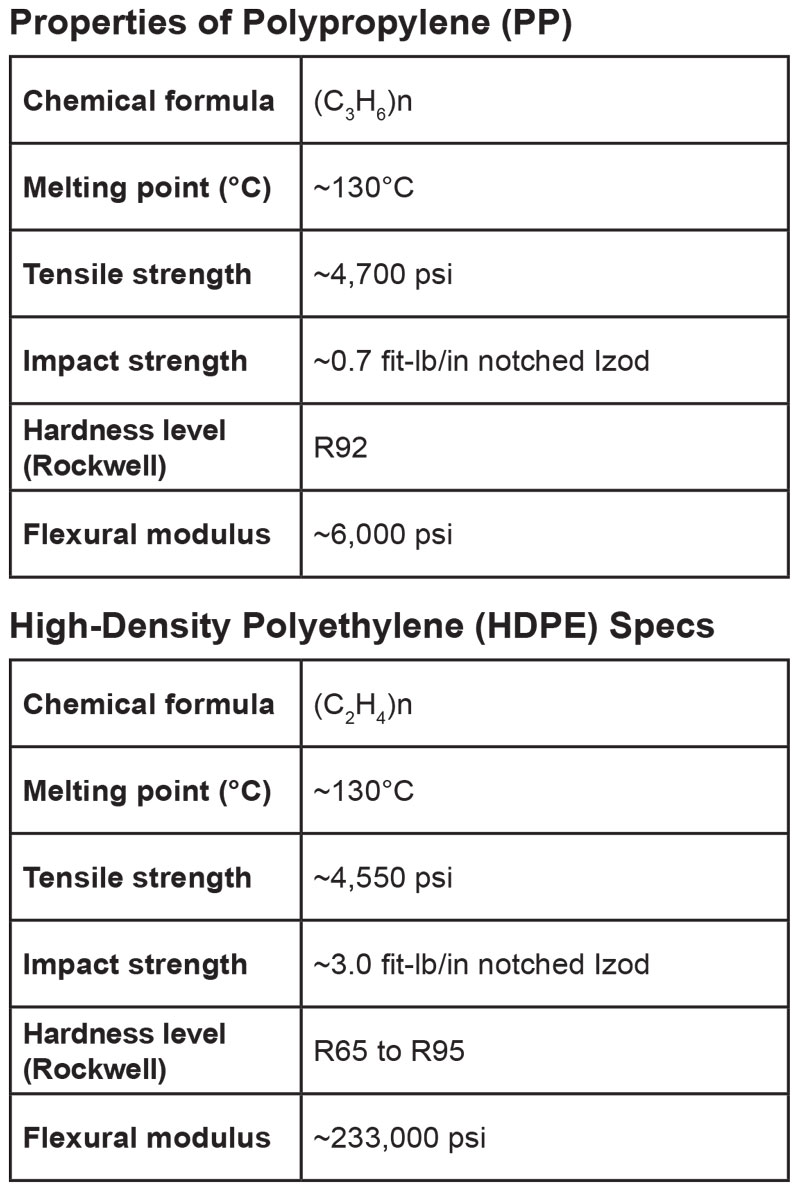

If printing problems cannot be resolved, consider using an alternative plastic that may have similar properties and easier to print or laser mark. This point emphasizes how critical it is for both designers and manufacturing engineers to develop the product specifications. Polypropylene and high-density polyethylene (HDPE) are less sensitive to molding, material and printing issues and less expensive. HDPE is the easiest of the three to print because it is more thermodynamically stable (see Figure 4).

Indelible laser marking on nylon is equally in demand because it eliminates adhesion problems and is less expensive to buy and operate. Laser-enhancing additives often are required to achieve either jet-black or opaque-white contrast.

As general background information about laser marking, recall that most polymers do not possess NIR absorption properties without chemical additives. New additives produce superior marking contrast and do not affect polymer clarity, spectral transmission or base physical properties. Both granulate and powder forms can be blended into precompounded color material or color concentrate.

Compared to ink printing processes, laser additives are cost-saving and can demonstrate 20% faster marking speeds vs. non-optimized materials.

In plastics gearing applications, nylons and acetals are widely utilized. Both are difficult to achieve adhesion bonding. Acetals (Dupont Delrin and Celanese Celcon) generally laser mark easier than nylon, are dimensionally stable and do not absorb moisture. Thus, laser marking of acetals becomes an ideal process, particularly since gearing products are offered in many substrate colors. For high-temperature engineering plastics PPS, LCP and PEEK utilized in electronic interconnect systems, laser marking also is preferred vs. ink printing.

Conclusion

Digital inkjet and fiber laser technologies offer countless advantages for product customization. Robust marking/printing solutions require precise engineering of ink/laser chemistries, polymeric surface science, process design and equipment. Each technology offers advantages and potential limitations. Many manufacturers already recognize the value of offering both technologies. However, digital offers the capability to print fully assembled products at the end of manufacturing operations, which offers cost savings and better inventory control management.

References

- S. Sabreen, “Innovating inkjet technologies for plastics products,” Plastics Decorating Magazine (Aug. 2013).

- S. Sabreen, “Fiber laser enables marking of advanced plastics,” Industrial Laser Solutions (Feb. 2013).

Scott R. Sabreen is founder and president of The Sabreen Group, Inc., an engineering company specializing in secondary plastics manufacturing processes – product security, laser marking, surface pretreatments, bonding, decorating and finishing. Sabreen has been pioneering technologies and solving manufacturing problems for more than 30 years. He can be contacted at 972.820.6777 or by visiting www.Sabreen.com.