Digital technology supports short runs and customization.

By Hallie Forcinio, writer, Plastics Decorating

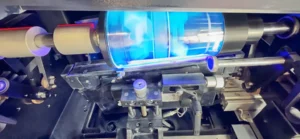

Digital inkjet printing ranks as a growing option for decorating 3D plastic parts. In some cases, it’s replacing spray, screen and pad printing because it can reproduce high-quality, full-color graphics. It also may play a role in in-mold decoration.

Digital inkjet printing of 3D plastic parts involves one or more printheads and may include systems for surface preparation or pretreatment, part feeding, static mitigation, drying/curing and post-coating to impart protective or gloss control properties.

When implementing inkjet printing, selecting the proper ink is critical because it must have the correct viscosity to form droplets. Proper pigment preparation is needed to allow ink to pass through nozzles ranging from 10-30 um.

“I very much believe in an ‘ink first’ approach to industrial inkjet,” said Mark Bale, Ph.D., director, DoDxAct Ltd., a supplier of laboratory services, consulting services and customized training for industrial inkjet projects.

He explained, “By this I mean it is important to determine if an existing screen/pad/spray [ink] chemistry can be modified (e.g., diluted) to accommodate the constraints of jetting. There often is a loss in function that comes from reducing the viscosity by dilution, [and] particle content should generally be less than 5 um. This is a challenge for matte coatings, where matting agents can be much bigger than this, and for thermochromic effects, for example. Most analog inks for metallic printing are also very difficult to handle in inkjet and have required new material development by players such as Eckhart.”

Compatibility between ink and printhead also must be assessed to ensure no negative interaction occurs. Printheads that are glued together with epoxy adhesive may fall apart if exposed to strong organic solvents. Generally, continuous inkjet printheads accommodate stronger solvents more successfully. “However,” Bale reported, “some suppliers of thermal inkjet or piezoelectric inkjet have been talking about heads that can handle materials like ketone (MEK, acetone), which could open up more graphic decorating applications.”

Plastic surfaces often require pretreatment. “It’s difficult to achieve adhesion on certain substrates,” explained Riley Mann, marketing specialist at Inkcups, a supplier of pad printing and industrial inkjet equipment, inks and other supplies. For absorbent substrates, this could involve application of a primer to prevent ink absorption and degradation of the image. More challenging substrates may require corona or plasma treatment to raise surface energy. It should be noted that some materials – like crosslinkers or adhesion promoters that may be mixed as “two-pack” – are less suited to inkjet.

From a curing/drying perspective, diluted inkjet inks may contain more solvent/water that must be removed. Bale added, “For ultraviolet (UV) curing using free radical chemistry, the low viscosity can have some complications for oxygen inhibition… This tends to increase photoinitiator levels.”

Beyond ink, substrate and adhesion, determining the feasibility of inkjet decorating of 3D plastic parts also depends on expected print area; production rates; and part size, shape and features like handles, which can be problematic due to their projection above the print surface.

Production rates depend on whether the inkjet system relies on scanning or single-pass technology. Single-pass systems may run faster than analog competitors because throughput is determined by linear speed. A scanning system likely is to be slower than its analog counterpart, especially for full-color printing, because the inkjet printer operates much like a home desktop printer.

Terry Clayton, Ph.D., chief scientific officer at Summit-Analytical, a specialist in product formulation, chemical sourcing and analytical support, explained, “The carriage scans over the substrate many times building the image in several passes. Resolution, carriage speed, step size and carriage turnaround time, all play a role in determining throughput.”

Process considerations also should be studied when considering inkjet decorating. Clayton recommended determining feasibility by working backward from the final product. “Look at each relevant area of the manufacturing process while constantly reviewing and revising the business case,” he said.

Citing disposal and recycling as an example, Clayton advised answering the following questions: Are there any requirements for disposal or recycling that will cause issues? Will the introduction of an inkjet process have any impact on end-of-life treatment? Does the use of inkjet ink change how the product can be recycled in a negative way? If so, can the chemistry be modified to eliminate any issues?

“Once this concern is addressed” he said, “the business case should be updated as necessary before moving on.”

Other process considerations include:

- Final product properties

- Manufacturing process

- Chemistry

- Curing requirements

- Pre and post process

- Manufacturing environment

- Regulatory considerations

- Unique customer application/versatility

Clayton also stressed the importance of having an inkjet expert work with experts in the decorating process currently in use to select the optimum ink chemistry and inkjet equipment for the application. He said, “This helps to identify both the advantages as well as the weaknesses inkjet may introduce. While evaluating each area related to the end product, constantly revisit and update the business case, making sure the strategy still makes sense.”

Advantages of digital inkjet

The major advantages of digital inkjet technology are versatility in materials (paper, plastics, fabrics, ceramics), run lengths from one-offs to production quantities and quick changeover.

“You can do one, two or six of this one, and then 12 of the next shape, just as simply as 500 or a 1,000,” said Michael Perrelli, marketing director at Innovative Digital Systems, a supplier of printing and surface treatment equipment and decoration services. “The technology fits applications that require full-color decoration, or even better – full customization – on quantities that aren’t profitable or feasible on other types of decorating equipment.”

Other advantages include:

- Instant dry time: Digital inkjet decoration with UV curing dries instantly using UV light from an arc lamp or UV LED technology, eliminating the need for additional drying time and enabling immediate handling and finishing.

- High quality: Digital inkjet printing delivers high-quality, full-color CMYKW images, ensuring sharp details, vibrant colors and smooth gradients.

Reduced waste: Digital inkjet technology eliminates both paper and plastic waste associated with traditional printing methods. Additionally, precise ink delivery systems minimize ink consumption. - Reduced lead time and costs: Digital inkjet essentially eliminates the prepress department in commercial printing as well as printing plates, screens and masking. The ability to print on-demand and avoid the setup costs associated with other printing methods saves time and money.

- Customization: One the main reasons manufacturers look to inkjet is for mass customization, integrating personalized designs, patterns, logos and branding elements onto 3D objects.

- Environmental: Inkjet printing typically employs environmentally friendly, water-based inks or UV-curable inks with low volatile organic compound emissions, making it a greener option compared to some traditional printing chemistries.

Limitations of digital inkjet

Limitations of digital inkjet technology vary depending on the printer model and ink formulation. But all systems involve a significant learning curve. “With any digital inkjet machine, training is an absolute necessity,” Mann noted.

Ink should be filtered to 1 micron, and customized ink chemistry may be required. Clayton said, “An off-the-shelf inkjet ink will not always be available for specific direct-to-object applications. Inks often must be custom formulated for adhesion, durability, light fastness or even regulatory requirements.” Although inkjet probably will reduce ink consumption, the inks tend to be significantly more expensive than analog inks, so ink costs can be a barrier, especially if the application is a low-cost product.

Capital investment costs can discourage inkjet implementation, especially when scaling to a larger process area. There also are limitations in printer size and substrate choices. “Despite advancements, there are still some substrates that are challenging to digitally decorate, even with proper pretreatment and specialized ink,” explained Mann. Material adhesion should be tested to ensure adequate performance.

Other limitations include the need to control the gap between printhead and object to ensure air turbulence does affect drop placement and image quality. Inkjet systems also require climate control so temperature and humidity fluctuations don’t affect printing. To ensure long printhead life, a clean manufacturing environment is essential to protect the printhead from damage from dust, fibers, stray UV light or contact with the substrate.

Tech advances

As interest in digital inkjet grows, the technology continues to advance. Perrelli reported, “Software for web-to-print continues to gain steam across companies of all sizes. Print-on-demand, overall production speed and printhead technology will continue to evolve as well. New ink formulations and primers could make difficult-to-print materials easier [to handle].”

He added, “UV flatbed printers will always be popular, but dedicated rotary machines continue to rise in popularity for both small shops and well-established brands involved in the drinkware industry [where]… customers want to go online, customize their item from their desk, tablet or phone – and have it arrive just the way they planned [it].”

Other innovations include different design techniques to expand the possibilities of the machine, specialized machines for specific applications or substrates and the combination of multicolor printing with engraving technology.

As inkjet moves into industrial applications, automation is critical. Clayton reported, “For flat substrates, lead edge feeders and stackers are common. However, for direct-to-object [printing], customized solutions including robotics are being used.”

In addition, he reported, several equipment manufacturers have worked to increase the carriage-to-table gap enabling object printing with a jig setup.