By Paul Uglum, president, Uglum Consulting, LLC

Artificial Intelligence (AI) has received a significant amount of attention and press recently. This raises the questions: How can AI be used effectively in the plastics decorating industry, and what value can it bring to plastic decorating?

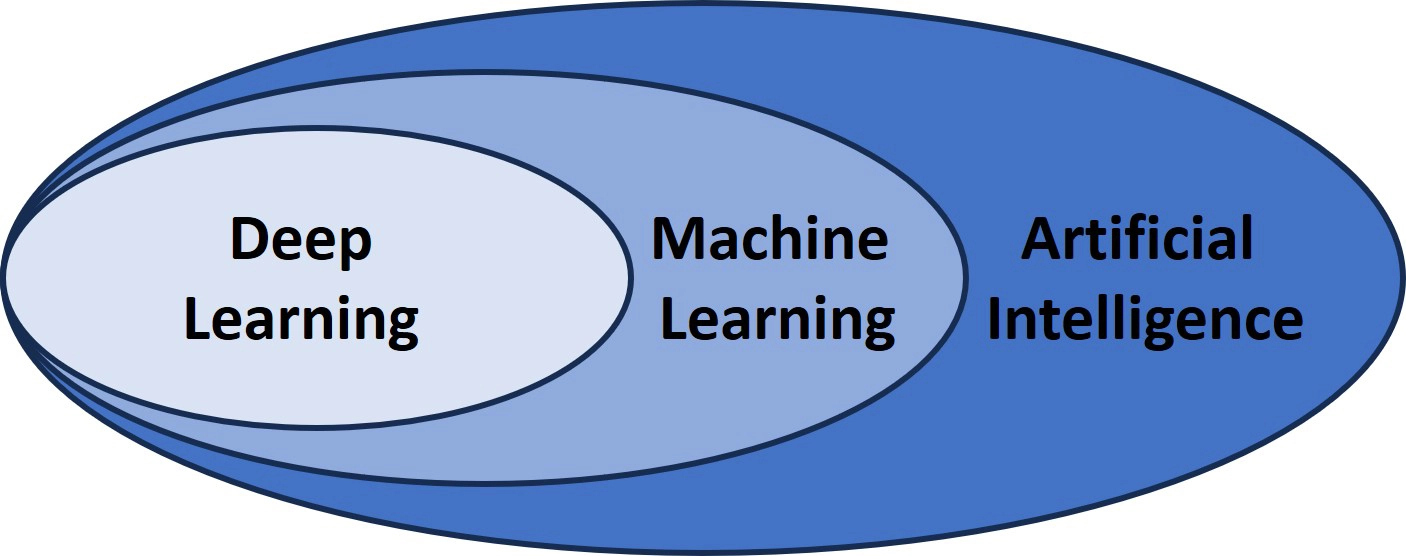

Artificial intelligence is the science of duplicating human thinking processes using computers. In a practical sense, AI involves using computers to do things that traditionally require human intelligence. AI’s advantage is that it can handle large amounts of data in ways people cannot. Artificial Intelligence is not one technique but an array of techniques. As such it is best to start with some definitions. AI is a program (and hardware) that can perform tasks normally associated with human intelligence but faster, and with an expanded range of capacities. Within AI there are subgroups, primarily machine learning, and within machine learning, deep learning.

Machine learning (ML) is the science of getting computers to learn and act like humans do. The approach is that the program is able to identify relationships in data and provide useful understanding. In effect, it can perform tasks without specific programming. Machine learning can be supervised, develop relationships between inputs and outputs and then continue to correctly identify outputs given new inputs. Machine learning also can be unsupervised and look for patterns in the data without defined outputs.

Deep learning is a technology that uses artificial neural networks to learn data and perform tasks without explicit programming. It uses large data sets for training, is very resource intensive and is intended for more complex tasks.

The world has huge amounts of data and information. AI is designed to convert this information into knowledge, understanding, insights and finally actions. The ability of AI to provide meaningful results depends upon two factors. One is the basic program (and supporting hardware). Does it contain any flaws or inherent assumptions that cause it to fail to correctly evaluate the data or create a biased outcome? The second is the data set available for evaluation. This includes both the size of the data set and the accuracy of the data set. The data can be the information (text) on the internet, if using a search tool, or the information coming from the internet of things (IoT) sensors used on production equipment. Above all else, AI can evaluate and comprehend much larger data sets than humanly possible. Unfortunately, there is a lot of incorrect and useless information on the internet and, if the information source contains errors, there is a risk of an unacceptable outcome.

The world has huge amounts of data and information. AI is designed to convert this information into knowledge, understanding, insights and finally actions. The ability of AI to provide meaningful results depends upon two factors. One is the basic program (and supporting hardware). Does it contain any flaws or inherent assumptions that cause it to fail to correctly evaluate the data or create a biased outcome? The second is the data set available for evaluation. This includes both the size of the data set and the accuracy of the data set. The data can be the information (text) on the internet, if using a search tool, or the information coming from the internet of things (IoT) sensors used on production equipment. Above all else, AI can evaluate and comprehend much larger data sets than humanly possible. Unfortunately, there is a lot of incorrect and useless information on the internet and, if the information source contains errors, there is a risk of an unacceptable outcome.

CURRENT USES IN MANUFACTURING

The use of AI techniques in manufacturing and plastic decorating is increasing. More applications are being developed and the maturity of existing applications increasing. A recent study looking at manufacturing identified the most common uses as predictive analytics, forecasting, image recognition, anomaly detection and natural language processing. The list of emerging applications is varied and growing.

In plastic decorating, some examples of AI applications are described in the following sections.

Predictive maintenance

Integrating AI with the IoT sensors allows continuous process monitoring, enabling AI to analyze patterns and predict potential failures before they cause unnecessary and costly downtime. This is critically important in industries with a high-cost impact of downtime or in processes, such as painting, that involve large, complex and expensive equipment. It also allows the selection of the appropriate maintenance intervals, thereby eliminating unneeded work.

Robot programming

Manufacturing is a data-rich environment. Adding automation and new processes increases the growth of data and the need for AI to manage it. Reliance on automation also increases the opportunity for using AI in robotics. AI allows operators to use natural language rather than code, reducing the need for specialized programming skills and increasing the speed of implementation.

Energy consumption reduction

AI can analyze energy usage, identify patterns and recommend operational adjustments. Painting is one of the more energy-intense plastic decorating technologies. Often ovens use heat to complete the cure of paint systems and large amounts of energy are used in air-makeup systems. Waste management and the pressurized air (used in part cleaning and atomizing the paint) also are significant energy consumers.

Image creation and artwork

Since decorating often can involve the creation and application of images to surfaces, the design of these images is of great importance. In the past, creating images was the purview of designers and artists. In a recent Graphics-pro article, there was a discussion of how creating art using AI works and how it can be used. The article reviews how AI allows the creation and iteration of designs much faster than with existing methods. The tools are trained on large numbers of images and image-to-text pairs. These programs do not cut and paste existing work, but work from a clean slate responding to the operator prompts. As a result, no two images are alike. AI also can imitate differing artistic styles using new subjects. It will be interesting to see how these tools are used in the future to develop new surface decorations. Beyond image creation, AI is being used for customization and product design.

Formulation design

AI has been used in optimizing coating and ink formulations. A recent Coatings World webinar discussed the value of AI in paints and coatings application engineering. It provided a good example of successful application of AI in an improved formulation development process. Using the extensive internal database, the supplier was able to construct a program that produces proposed formulas that meet defined performance and cost requirements. It has been used to quickly provide potential formulas to test optimized performance with cost-effective alternatives. The database looks at 100 data points per formulation and allows fast responses to changing market and performance needs. The webinar presenters reported that the program took six months to train to the point where it could be implemented as the primary design tool, so there is some investment in time and effort to create a working program.

VISUAL INSPECTION – QUALITY CONTOL

One application that holds great promise for AI use in plastic decoration manufacturing is part inspection. Many decorating processes depend upon human visual examination as a part of the normal process. This is because of the dual issues of random defect locations and the occurrence of unexpected visual anomalies. This dual problem makes programming conventional vision systems for comprehensive defect detection either difficult or impossible. With the proper use of lighting, vision systems and possibly fixturing, it should be possible to reliably identify both expected and unexpected defects. AI using vision systems can identify anomalies and defects at speeds and accuracies that are not possible with human inspection. Since all processes have variability and produce anomalies, it becomes all the more important to understand and document what constitutes an acceptable and unacceptable part to the customer. AI will both increase the reliability of inspection and, more importantly, provide a platform for process improvement.

RESEARCH AND WRITING USING CHATGPT AND SIMILAR TOOLS

The reliability of AI tools in answering questions, aiding internet searches and creating documents still is in question. There unfortunately are too many examples of poor or dangerous results using programs such as ChatGPT. Care should be taken when using AI to do research or write documents.

AI depends heavily on machine learning in which the software identifies patterns without predetermined rules. The software uses neural networks, which are inspired by the architecture of the brain. The nature of how these patterns are developed can be very difficult to identify and understand. This means many are “black boxes” with structure that is obscure. Understanding especially is difficult for large language models (LLMs), such as ChatGPT. Although they have been used to identify medical diagnoses, write code and draft academic papers, they have unfortunately also been known to generate misinformation. Some believe that LLMs write by probabilistically combining patterns of text they’ve seen before, without understanding the substance of what they are writing. Others consider they have some level of reasoning, and still others believe they construct models of the world that they use to provide answers. In any event, LLMs can react erratically.

Google’s AI Overview can give false, misleading and dangerous answers. This is, at least in part, due to the sourcing of the information. AI does not necessarily recognize jokes. In one example, it recommended adding glue to pizza to keep the cheese from sliding off. The source of this recommendation was traced to a post and someone’s sense of humor. There also can be issues when dealing with sources that do not agree. So, the questions are: Where is AI getting its information from and how it resolves discrepancies? There are no small considerations in technical fields. Periodical Journals are the primary route by which new research is to be reported. In 2023 alone, over 10,000 flawed papers were withdrawn due to poor quality, errors and fraud. Peer-reviewed papers are not necessarily all that safe either. Some suffer from poor application of data analysis or have results that cannot be replicated, and others contain outright fraud.

AI FOR INVENTION?

AI is not a solution to everything. Consider what human intelligence is being replicated. Is it observing, gathering knowledge, understanding, deciding or creativity? AI appears to currently be able to observe, document and interrogate data, analyze data for patterns and, depending upon the program, create a basis for decisions and solutions. Used properly, AI can identify trends that people cannot see. Its inventive capability is less apparent. Inventions often are the result of efforts to meet specific needs. Inventive thinking typically involves combining concepts or elements from different realms that would not normally be put together. When looking at how inventions occur, they often are the result of a foundation of previous discoveries and work (as documented in James Burke’s book “Connections”) or the application of new technology to previously untenable solutions (as in Dean Kamen’s invention of the Segway). AI can be very creative, but true inspiration and leaps in logic are less certain. AI’s strength is the ability to access knowledge across a broader reach than any person or group. Inventions resulting from innovative combining of technologies or reaching across differing fields should be possible with AI. Inventions resulting from “insight” and “inspiration” may not be.

POTENTIAL ISSUES

One of the main barriers to the implementation of AI is the quality and availability of data. Not a lot of literature concerning plastic decoration exists on the web. Many companies consider their techniques proprietary and, as a result, much useful information is not readily available to AI. Poorly selected sensors, similarly, can provide flawed data or miss the critical characteristic to be monitored in a process.

One limiting factor that has not received as much attention as it should is power usage. Nothing is free. ChatGPT searches use 10 times the energy of a typical conventional search. Most AI activity takes place in large server farms. These consume very large amounts of current and, in some cases, create stress on the utility grid. This will be an increasing problem as countries attempt to achieve carbon neutrality at the same time as they increase power consumption.

Finally, government regulation of AI is becoming an issue. An online summary of recent European Parliamentary legislation reports, “The European Union’s (EU) Artificial Intelligence (AI) Act is a binding law that aims to protect fundamental rights, democracy and environmental sustainability from high-risk AI.” It is expected that there will be more regulation in the future. The intent is to protect the user and general public from negative and intrusive applications of AI, but as with any regulation, there will no doubt be unintended consequences.

FINAL THOUGHTS

The greatest strength of AI is the ability to comprehend massive amounts of data in a way that is not humanly possible. This makes AI not just a tool of convenience, but a necessity in many applications. As applications grow and become more mature, there will be increased use in manufacturing environments.

AI, in its many forms, is just another tool available to designers and manufacturers. As with any other tool, the choice to use it or not use it is a business decision. The important questions are: Does it improve the product, in this case, decorated plastic? Does it help the business be more successful (faster, lower cost, more competitive)? As with many tools, it is a decision that should be made on a case-by-case basis, and because of the significant rate of change in the field, regular evaluation should occur to see if the underlying conditions have changed.

Paul Uglum has 43 years of experience in various aspects of plastic materials, plastic decoration, joining and failure analysis. He owns Uglum Consulting, LLC, working in the areas of plastic decoration and optical bonding. For more information, send comments and questions to paul.a.uglum@gmail.com.