By Paul Uglum, Uglum Consulting, LLC

One useful feature of decorated plastic surfaces is the ability to selectively backlight through them. This adds a whole new dimension to traditional plastic decorating and can be used either for aesthetic effect or to provide information needed to operate the completed product. Choosing this option greatly enhances the visual impact and functionality over a wide range of applications. Lighting can do so much more than just provide color and brightness. Lighting can influence emotion, it can help to provide end customers with orientation with respect to the product, and it can be used to communicate information. Unfortunately, the addition of backlighting also greatly increases complexity and the difficulty in successful product execution.

Plastic decoration by its very nature is a complex ecosystem of processes, materials and support technologies. Given the range of substrates and applications, it is a complicated environment that takes skill and knowledge to navigate. In the case of illuminated (backlit) decorated plastic, additional layers of complexity are added. This means that the knowledge required to successfully implement the needed technologies resides in more than one field of expertise. Further complicating the issue, several decorating technologies often are used in combination to produce the desired product outcome. This adds the requirement of understanding how these techniques work together, both functionally and optically.

Applications of backlighting of decorated plastic are generally characterized as either ambient lighting and/or functional lighting. Ambient lighting is intended primarily to enhance the appearance, create an impression and define the brand character in an application. At the same time, it can provide some minimal lighting under low-light conditions and allow customers to orient themselves in the environment.

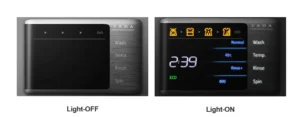

In the case of functional backlighting, the purpose is to inform and communicate to the user in the operating environment. Functional backlighting can take the form of graphics on buttons, which indicate the operation the switch performs, or in the case of capacitive switching, identify where to touch the surface to activate the switch. It also can be used as an indicator or warning. The graphics or features can always be visible or in other cases visible only when backlit. Functional lighting also can convey information by changing color or by varying the intensity and location of the lighting. It can create the illusion of movement using sequential illumination, thereby creating dynamic lighting features.

Backlit decorative plastics are found in a wide range of markets including automotive, consumer products, appliances, computers, telecommunications, signage and many others. Although some applications have been replaced by the advent of display technologies, new and innovative applications continue to appear. Plastic decorating has long provided value beyond the aesthetics and protective properties and has been integrated with other technologies to facilitate smart surfaces featuring not only lighting but including functions such as switches, sensors and haptic feedback.

Designing with light

When creating a backlit feature, the first step is to understand what the customer wants and how to define both the lit and unlit appearance. Part of this is determining just how intense the lighting must be to be visible under regular conditions, yet not so bright as to be distracting. Lighting can be either subtle or bold. In some applications, a constant light intensity will be acceptable. Other environments need adjustable intensity levels; this will require circuitry to automatically adjust the lighting intensity depending upon the surrounding light levels or manually adjustable lighting.

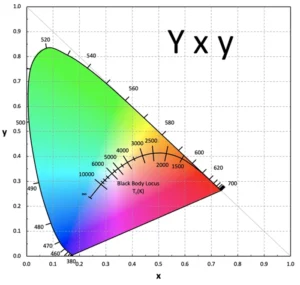

When measuring emitted light, it is important to understand that numerical values alone do not describe the observed appearance. Two graphics with the same intensity will not appear to be equally bright if they are of different surface areas. The larger area appears brighter to the user even though the measured light intensity is the same. For this reason, it is important to maintain the consistent stroke width in graphics on buttons and design so the lit areas have similar surface areas. The brightness or intensity of the lit surfaces should be measured as luminance in candelas per meter squared, Cd/m2. This can be measured with either a luminance meter or, if color information is needed as well, with a spectroradiometer. In either case, the instrument should be chosen so that the measured area is smaller than the feature to be measured. In general, measurements are made normal to the surface. When making measurements of colored light, the color is reported in CIE 1931 color space, Yxy, where Y is the light intensity in Cd/m2 and x and y are coordinates in color space.

When designing a backlit decorative plastic application, it is important to understand the environment in which it will operate and what the performance expectations are over all levels of the surrounding light. The choice of light intensity (brightness) always is application specific.

How bright is bright enough? It is important to consider the range of viewing conditions under which the backlighting must operate. Making an image visible in bright sunlight requires a much higher intensity for indoor or low-light conditions. For sunlight conditions, the intensity may need to be over 1500 Cd/m2 while for night applications in automotive, 8 or less Cd/m2 may be adequate. A typical cell phone display is over 500 Cd/m2. The right answer depends upon the application including the lit surface area and technologies chosen.

Lighting and light delivery

In designing the backlighting, the system includes the light source, how the light is transferred from the source to the decorated plastic part, what happens to light as it passes through the plastic and decoration and how it reaches the eye.

The foundation of a backlit system is the light source. Light-emitting diodes, LEDs, have become the primary light source of choice in many designs due to the availability of a wide range of colors, intensities and packaging options. The use of LEDs as a light source has greatly expanded the possible applications, reliability and range of design options for backlit parts. Other lighting technologies do exist, but LEDs are currently the dominant technology.

LEDs work by passing electrons through a semiconductor die, which in turn produces light in a narrow range of wavelengths. LEDs provide a reliable, long-life source with a low current draw. White lighting can be achieved either by color mixing (red, blue and green LEDs) or by the addition of light-emitting phosphors to a blue LED package reasulting in a white appearance in a wide range of color temperatures. Color mixing using red, blue and green dies also can be used to achieve any customer-selected color within the gamut defined by the LED wavelengths. Dynamic appearances can be created by changing the intensity, color or state (lit/not lit) across a surface. Because of variation in the manufacture of LEDs, in order to achieve a common color or intensity, it is often necessary to bin (sort by color and intensity). Although it is acceptable to have variation part to part, it is important to control which LED bins are used within a given lighting system in order to avoid noticeable differences within product.

Once light – in the color and intensity needed – is produced, it is transferred to the component to be backlit. There are several options for delivering light – direct backlighting, light pipes, light boxes and fiber optics all are possible solutions. The best depends upon the design and performance requirements. Often the entire package size is constrained. LEDs create focused hot spots of light so the light delivery system must be designed to evenly distribute the light across the surface that is intended to be lit. To create an even lighting result, it is often necessary to use light-scattering materials.

There are two issues to consider: One is creating even lighting and the second is not reducing the intensity or changing the color (by selectively absorbing part of the color spectrum). Polycarbonate often contains a small amount of blue dye to combat its slightly yellow appearance. In long light pipes, color changes in white light can be observed. Finally, light can be directional; leave the lit surface in such a way that it is easily viewed in the application.

Technologies for manufacturing backlit parts

Backlightable decorated parts can be made using many decorating technologies and combinations of technologies. All methods consist of a structure that transmits light and defines the lit and non-lit surface using opaque and translucent features.

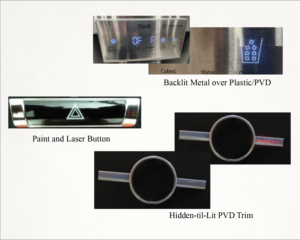

Paint and laser technology are commonly used to make backlit parts for buttons and some larger parts. Conventional paint and laser parts are made by applying one or more layers of paint to the part and removing the light-blocking layers by laser ablating down to the translucent surface. This often is done using a YAG or fiber laser and can be highly automated. Not all paint formulations and colors are easy to cleanly laser, so some trials may be necessary. Day-lit colors can be achieved with colored translucent plastic, with paint or pad print colors. Neutral density dyes can be used to create black graphics that can be backlit.

Although not decorated plastic as such, two-shot plastic parts with translucent and opaque plastics can also be used. The issues with this option include shadows, caused by bridges on the reverse side of enclosed graphics, the required intensity of the backlight source and the cost of modifications to the lit design if needed.

In-mold decorating

In-mold decorating (IMD) is the most versatile technique to create backlit surfaces. This technique offers the widest range of capabilities including organic shapes and some level of customization. Some of the most value-added and complex backlit structures are made using film insert molding. This group of technologies provides the ability to produce a wide variety of images and textures and is the best option for large and complex surfaces. IMD also is very effective in creating smart surfaces that incorporate technologies, including lighting and other functional electronics. One popular feature is the ability of this technology to provide images that remain hidden until lit. This goes by various trade names including HiddenIcon and Shy Tech.

How to make backlit metallic appearances

The German newspaper Süddeutsche Zeitung once referred to “light is the new chrome” when discussing the increased use of lit features in automotive applications. Fortunately, it is possible to create backlit metallic features, providing both a chrome appearance and a lit surface.

Metallic paints can be used to create a painted and lasered image for backlighting. Metallics can be difficult to laser cleanly, and a black base coat often is required. In-mold using either metallics applied to the film using either physical vapor deposition (PVD) or bright metallic inks both create a metallic appearance. A range of metallic images – from matte to specular appearances – is possible. The galvanic process can be used to make metallic buttons with backlit graphics by either plating two-shot parts with plateable plastic for the metallic portions and non-plateable plastic for the areas that are to be backlit. PVD can be used to make metallic buttons and the graphics can be laser ablated onto the finished part. Real metal surfaces with micro holes applied over plastic surfaces can provide backlit graphics and images as well as provide a cool-to-the-touch feel.

Risks

Adding backlighting also creates new failure modes that are not present in decorated parts without backlighting. They are primarily either forms of light leaks or uneven light. Light leaks can be due to poor design or if the materials blocking light have inadequate hiding power either due to the pigment chosen or due to poor distribution of the pigment. If the light-blocking layer of ink or paint has poorly distributed pigments, backlighting can produce a galaxy effect where there are many small light leaks. Similarly, defects due to inadequate thickness or coverage can produce single-point light leaks. Uneven lighting can be the result of poorly distributed pigments in the translucent layer, which creates a cloudy, mottled appearance in the lit surface, or caused by poor light delivery design or execution.

Conclusion

As with all plastic decorating, it is important to understand the technologies and to involve experts in all aspects of the design at the start of the process. Adding or changing direction late in the program greatly increases risk and cost. More so than with other technology combinations, it is important to involve (or develop internally) expert teams to design and execute world-class backlit decorated parts. A few film and process suppliers have developed significant expertise and are willing to work with their customers to provide outstanding finished parts. The In-Mold Decorating Association holds conferences and its members have an extensive knowledge base in applying IMD to lighting applications. n

Paul Uglum has 43 years of experience in various aspects of plastic materials, plastic decoration, joining and failure analysis. He owns Uglum Consulting, LLC, working in the areas of plastic decoration and optical bonding. For more information, send comments and questions to paul.a.uglum@gmail.com.

References

Light Measurement Handbook by Alex Ryer, 1997, International Light