By Mike Gizzi, service and calibration manager for Ultrasonics at Emerson

Preventive maintenance (PM) is an essential factor in ensuring that equipment operates at its peak performance. It helps identify potential problems before they escalate into major, costly problems. It is proven to reduce downtime, increase quality consistency, extend the life of the equipment and ensure equipment operates safely and as expected.

The first step in establishing a preventive maintenance program, whether the ultrasonic equipment is brand new or has been in service for a while, is to establish a maintenance baseline. It’s a program of inspection followed by logging data.

New equipment can be started on a two-month maintenance schedule where results can be logged. Equipment owners can continue this process for a few cycles, and, if the equipment is running without a problem, intervals can be extended to every three months. As time goes by, equipment owners will develop a clear understanding of the best maintenance interval schedule for the equipment in the owner’s manufacturing process.

Setting up a baseline for equipment already in service requires the owner to start by reviewing all its current maintenance logs. Knowing the history of the equipment makes the PM process easier. Check what maintenance predecessors have done and how the equipment has performed. Identify the original weld parameters and stack components for each application (e.g., frequency, amplitude, downforce, energy input) and see whether they’ve been modified over time.

Equipment that has had modifications to its original weld parameters or stack components may have had maintenance problems. Technicians sometimes can take shortcuts to needed maintenance by altering weld parameters (e.g., increasing amplitude, changing to a higher gain booster) to compensate for aging stack components or a worn-out horn. Such “Band-Aid” fixes aren’t recommended and can result in more costly repairs later.

If previous log data indicates any decline in weld quality, it’s a sure sign that something is wrong. Look for data indicating uneven or incomplete welds, inconsistent weld appearance, uneven wear of the horn, a “sluggish” actuator, or the perception that the weld process is losing power or needs more power. In addition, a worn anvil – the fixture that holds the lower part of the assembly during welding – also could be a cause of uneven or inconsistent welds.

TOP PREVENTIVE MAINTENANCE CONCERNS

To understand the benefits of PM, consider the kinds of problems or failures that are trying to be prevented and how these problems occur.

Item 1: The Stack

The number one maintenance item on an ultrasonic welder is the “stack” components: the converter, booster and horn. These components are selected or custom-built to suit the welding application yet, like an engine, are subject to stress and wear over millions of cycles.

At the top of the stack is the converter, which mounts to the welder’s actuator assembly. It “converts” electrical energy from the power supply into mechanical energy (frequency/amplitude). Next, the booster “steps up” or reduces the amplitude (vertical motion) needed for the welding application. At the bottom is the horn, which transmits the frequency and amplitude of vibration under downforce pressure from the actuator to the contours of the part or film to complete the weld.

Repeatable welding, therefore, relies on consistent, efficient energy transfer through the stack, which in turn relies on mechanical interfaces and connections in the stack. The converter bolts to the actuator, the booster is torqued to the converter and the horn is torqued to the booster. Between these mechanical interfaces, there are threaded studs, special washers (e.g., Mylar) or greases.

Stack PM

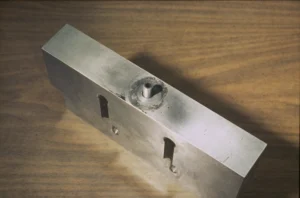

A PM program should aim to keep the entire stack properly tightened and aligned for maximum performance and life. Stack components usually connect using threaded studs or bolts that are assembled with a specific level of torque. Ordinary stress and vibration can cause these connections to loosen, so check and re-torque them periodically. Equipment owners will want to minimize “fretting” wear in stack components. Fretting occurs under load, when minute irregularities on opposing surfaces stick together under compression but break apart under oscillation or slippage, resulting in material loss. The first surfaces to be affected are the washers that fit between stack components. Worn washers deteriorate into a dirt-like substance (Figure 1), while fretted metal surfaces appear discolored or corroded.

Typical stack PM should include:

- Remove and inspect stack periodically.

- Disassemble and check washers, stack components and horn surfaces for wear, using factory-recommended procedures.

- Replace washers if needed.

- Recondition metal components using factory-recommended procedure or replace if severely worn.

- Reassemble and re-torque to factory specifications before reinstalling.

of Emerson.

Item 2: The Actuator/Air Cylinder

The second vital PM item on an ultrasonic welder is the actuator assembly, which (usually) includes a pneumatic air cylinder to provide downforce. This relies on a “clean, dry” compressed air supply because any moisture, oil or particulates can greatly reduce the life of the cylinder piston and seals. Oil or water contamination in compressed air supply lines are the leading causes of cylinder wear, which can cause actuator motion to become sluggish.

Oil contamination occurs because aging and worn compressor pistons allow oil blow-by, resulting in oil droplets or yellow-brown staining (Figure 2) in air supply lines. Oil bleeder valves can help capture and contain some oil contamination, but if there’s a significant problem, a new air compressor may be needed. Water contamination can occur anytime but is the worst in the summer when relative humidity is highest. Users may report that actuators are sluggish, air cylinders are “sticking,” solenoids aren’t working properly or droplets of moisture are appearing in air supply lines. Often, the root cause has to do with poor performance or a lack of capacity in the facility’s compressed air-drying system. Check that first.

Typical actuator/air cylinder PM should include:

- Open actuator housing and inspect air lines for droplets or discoloration.

- Inspect and clean air cylinder and filter.

- Bleed fluids or dirt from the filter.

- Disassemble and clean when necessary, using factory-recommended procedure instructions. Replace filter if dirty, wet, or leaking.

- Empty oil bleeder valve.

- Check and maintain compressed-air drying system.

Ordinarily, pneumatic cylinders are so reliable that they rarely need replacement. However, some organizations validate cylinder operation by testing weld force (downforce through the actuator) on a monthly or regular basis. If the value on the welder power supply equals the force value on calibrated test equipment, the cylinder and actuator are operating normally.

Item 3. Welder electronics

Welder electronics are engineered for high reliability, so they generally are trouble-free. The key thing here is visual inspection. Over a period of time, the up-and-down motion of the actuator, which houses the wire bundles that bring power to the converter, can cause fatigue and wear in the wiring. Signs of wear include brown, darkened or cracked areas on wire insulation, or on the tubes that carry the wires. Any failure in this area requires factory service.

CONCLUSION

Fortunately, because ultrasonic welding of plastics is a mature, highly reliable technology, the most-common operating and maintenance challenges are well understood. Decades of technological development have resulted in equipment that combines durable design, advanced digital technology and consistent operation, and welding problems usually can be prevented or resolved relatively quickly if an up-to-date, regularly scheduled maintenance program is in force.

While this article provides basic PM guidelines, effective PM always must be based on practices and procedures published by the equipment manufacturer. For more information on Branson Emerson, visit www.emerson.com/en-us/automation/branson.

Mike Gizzi is global service and calibration manager for Branson™ ultrasonic plastic and metal welding at Emerson. His 38-year career with Emerson includes 15 years in ultrasonic product electronics, manufacturing and testing, and more than 20 years in managing service and repair operations for Branson ultrasonic cleaning, plastic welding and metal welding equipment, as well as National Institute of Standards and Technology (NIST) calibration operations for Branson ultrasonic welders used in medical product manufacturing.