By Paul Uglum, Uglum Consulting, LLC

What would plastic decorating be without color? At its core, plastic decorating relies on the ability to produce a wide range of colors and to place them wherever wanted. This is in a world where plastics themselves are relatively bland and where the resins and other components of paints and inks also are relatively without color. Since one of the strengths of plastic decoration is its ability to produce a wide range of attractive appearances, it is good to understand where color comes from and understand what the advantages and limits are to the various technologies used to achieve color.

Color is central to creating desirable products. Color also is strongly associated with brand identity and, as such, must be produced to the highest standards. It is worth understanding how decorated plastics are colored since this influences not only the appearance and performance, but also the failure modes of the final product.

Molded plastics can be colored with the inclusion of pigments and dyes in the formulation or by transfer technologies, such as dye sublimation and polymer dying (used, for example, with additive manufactured parts). In many cases, the use of a colorant in the molded plastic part is adequate, in other cases secondary decorating processes are needed to achieve the desired appearance; and performance. Although sometimes effective, there are significant limits to molded color, especially with metallics and some effect pigments.

Paints and Inks

Most decorative processes rely on paints and inks at some point during the manufacturing process. Paint or ink is a liquid, usually containing a binder, solvent, pigments and additives. Paints and inks are not an end product but an intermediate product whose properties depend not only upon the formulation, but also upon the manufacturing process through which they are applied.

Part of the process of producing paints and inks is adjusting the color when the batch is completed. Variation, in both materials and process, often makes it necessary to do final adjustments (tinting) to the formulation to match the color target (master). In an ideal situation, these adjustments are few. In the worst case, many adjustments can lead to an inferior product, leading to an undesirable pigment-to-binder ratio, which can result in a loss in final properties.

Although most decorators do not formulate their own paints or inks, the formulation from the supplier can have a significant impact on the finished product and is worth understanding. It also is useful to understand the variety of possible appearances available and limits in the range of each appearance. Formulators are unlikely to share the exact contents of their formulations, but knowledge of the general type of colorants is useful in making good design decisions.

Developing Colors

When colors are being developed, many times there are conflicting requirements to consider. These include the color criteria, processing requirements and economic and environmental demands. In order to satisfy all parties, the design of the part often is a compromised solution. A basic rule when developing solid colors is to keep the pigmentation as simple as possible. Typically, solid shades require four pigments: two chromatic pigments to adjust the hue and two achromatic pigments (black and white) to adjust for the lightness and chroma level.

Performance requirements should include good hiding power, negligible metamerism, environmental resistance and process repeatability during application by the decorator. It is important to establish the performance requirements for the chosen application prior to choosing technology to avoid known failure modes.

Color fastness is the property of the color not changing after long periods in the use environment (weathering and UV exposure, for example). Some pigments, such as daytime fluorescent colors and some organic dyes, traditionally have poor performance when exposed to direct sunlight. Hiding power is the ability of a paint or ink to hide the color or color differences of the coated surface.

Black and White

Carbon black, in its many forms, has long been the choice for black pigmentation. For example, it provides a good foundation for systems requiring laser ablation when creating backlit graphics. Carbon black consists of pure micro crystalline carbon produced by the combustion of hydrocarbons in an oxygen-deficient environment. Carbon blacks are low cost and exhibit outstanding weather and chemical resistance, as well as high tinting strength, which makes them the pigment of choice. In addition to color, they can provide electrostatic dissipation on plastics.

Some very black surfaces are possible. Although not a pigment but a coating, Vantablack (Vertically Aligned Nano Tube Arrays). is capable of absorbing 99.9% of light. When looking at coatings, the least reflecting coating is Musou Black, which absorbs 99.4 % of light and is made with multiple blacks, nano-scale pigments and specialty polymers.

The go-to white for the industry is titanium dioxide (TiO2) with the rutile crystalline structure. Its high refractive index of 2.75 makes it superior to other types of white pigments. White lead historically was used but is no longer in use due to its toxicity.

Metallics as Pigments

A wide range of desirable appearances, including very specular (reflective) surfaces, are possible when using metallic pigments. Characteristics of a metallic coating or ink are dependent on the particle shape and size. Brightness, brilliance, color saturation and flop (brightness changes at different viewing angles) improve with larger particle size, while hiding power and distinctness of image increase with finer partial sizes.

The wetting properties of metallic pigments are critical to how they behave and can be controlled in various ways. Pigments that are oriented toward the surface of the film are called leafing pigments. Pigments that are better wetted by the binder or solvents and are more evenly distributed in the coating are called non-leafing pigments. Larger metal flakes, 25 microns or larger, can be used to create sparkle effects and can be added to straight shades to create attractive effects.

Although there is a strong desire to use water-based technology to meet safety, compliance and perceived sustainability requirements, there is a significant risk with metallic pigments. Aluminum pigments react with water to liberate hydrogen; this means that the pigments must be passivated and the pH of the coating controlled to prevent the reaction. This limits the availability of some pigments. Another issue is that, when painting large surfaces, there is a risk of non-uniform pigment orientation, resulting in a cloudy appearance if the coating is not properly compounded.

Multi-layer Options

More complex and attractive appearances can be achieved by using more than one layer of coatings with different pigments and dyes in each layer. The anodized appearance is achieved by coating an opaque metallic appearance with a colored translucent topcoat.

Effects Pigments

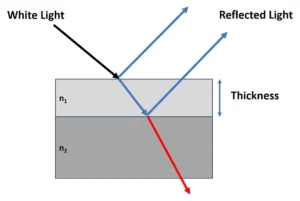

Pearlescent and metallic-effect pigments represent a class of more complex color systems. These pigments rely on platelets that are coated with a very thin layer of metal oxides which produce color by reflected light via interference. The thickness of the coating determines the observed color. Unlike solid colors, the appearance of effect finishes changes with viewing angle and illumination conditions.

In the case of pearlescent pigments, the substrate often is synthetic mica and the coatings are either titanium dioxide or iron oxide. This creates a pigment that is light reflective while at the same time has a degree of transparency. This allows the coating to have a sense of depth but also means that the color of the substate is a part of the overall appearance. White pearl reflection color is produced by using uneven titanium dioxide coating thicknesses, resulting in a mixture of colors being reflected and resulting in a white appearance.

Several factors influence the luster and appearance. These include flake orientation, particle size, pigment concentration and how transparent the coating is.

Self-Assembling Structural Color Paints

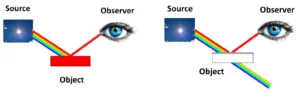

One new coloring solution is structured color, which requires no colorants (dye or pigment). BASF and Cypris Materials have jointly worked to introduce the use of self-organizing polymers to create color. The color is achieved using rapid self-assembly of brush block copolymers, resulting in a multi-layer photonic crystal – much the same as in morpho butterfly wings. BASF introduced the coating ZENOMENON and received the Red Dot Design Award for this innovation.

The color saturation can be significantly higher than traditional colorants, resulting in high chroma (very vivid colors) that can be tuned to differing colors by adjusting the molecular weight of the polymer. Since it is relatively translucent, the substrate color influences the appearance. It can be applied with conventional processes, including spray coating, screen and digital printing.

Advantages include radar transparency, which can be a significant issue with many pigmented systems, a reduction in manufacturing waste and improved recyclability due to no pigments. In addition, between 30% and 50% of the structural color layer is made from bio-based renewable raw materials.

Regulations

Pigments and dyes have been used for millenia to decorate all types of products and have a long history. Many pigments, such as white lead (white) and cadmium-based pigments (yellow through bluish red), are no longer in use due to their toxicity. An important question to consider is, “Which pigment systems are at risk for future regulation, either due to their toxicity or their impact on recyclability?” It is important to stay up to date with current proposed regulations in order to allow time to develop replacements as needed.

Many regulations impact the choice of pigment and dyes in inks and coatings. These include California Proposition 65, which lists many chemicals that can cause cancer or reproductive harm, and the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) Regulation, a European Union (EU) law that protects human health and the environment from the risks of chemicals. In the case of food packaging and medical applications, there are even more stringent regulations.

In addition to concerns about toxicity, there is an increased focus on environmental impact and the circular economy. Recently, the Eco-design for Sustainable Products Regulation (ESPR) came into effect in the EU. This regulation seeks to improve product durability, upgradability and repairability by making products more energy – and resource-efficient, addressing substances that inhibit circularity and making it easier to remanufacture and recycle products. The standard applies to all products sold in the EU, as well as those manufactured there.

Conclusion

This is, at best, a brief introduction to where color comes from in decorated plastic. No one color-producing technique or technology will meet all product needs for appearance and performance. During the design phase and early implementation phase, it is important to understand the capabilities and limits of the chosen technology. These are discussions that should take place and should involve the entire value stream, including the manufacturing site and the suppliers of the ink or coatings. n

Resources

Nassau, Kurt, “The Physics and Chemistry of Colour – The Fifteen causes of Colour,” John Wiley & Sons, New York, 2001

Book, John et al., “Self-Assembling Structural Color Paints,” Paint & Coatings Industry August 2023

Kettler, Wilhelm et al., “Colour Technology of Coatings” Vincentz Network, Hanover, Germany, 2016

Wissling, Peter, “Metallic Effect Pigments, Fundamentals and Applications,” Vincentz Network, Hanover, Germany, 2006