By Paul Uglum, president, Uglum Consulting, LLC

Plastic packaging in its various forms is pervasive; everywhere one looks, products are packaged in plastic. This is because plastics are singularly effective in meeting the packaging needs and customer expectations in a wide variety of applications. These include a broad range of markets from foods and medications to household, personal products and high-end cosmetics.

One of the strengths of plastics, as a packaging material, is that it can be decorated using a number of processes. Plastic decoration is used to convey information, define the brand, ensure security and increase the desirability of the product. Plastic packaging, without decorating, would be both less effective and bland, missing both the desirable appearance and important product information added in the decorating process.

Plastic packaging is used to meet a number of important requirements. It allows the purchase of defined amounts of a product in a container that protects the product and protects the customer by providing a container that is clean (biologically safe) and secure from tampering or alteration. For all products, the purpose of packaging is to protect the contents during the entire product life cycle from the point of manufacture, through transit, while on the retail shelf and finally to the customer. Proper packaging design reduces waste and can contribute to a circular economy. For food and medical products, the standards and requirements are more stringent because of consumer safety and product protection needs. Studies have found that packaging design influences customers’ purchasing decisions for cosmetics and household products. Decorated packaging, therefore, has the additional purpose of making the product attractive to the customer.

Decorated plastic packaging is not one technology, but several that respond to the differing needs of each application. Although the fundamental role remains the same, the range of applications varies from lower-cost disposable to high-end cosmetic packaging. Packaging types range from flexible packaging, which can change shape when filled or as it is being used, to rigid containers, bottles and closures. Of the packaging types, flexible packaging is the largest market segment and amounts to about a $44 billion market and continues to grow despite legislative and regulatory impacts. All forms of packaging require decorating processes or labeling as a part of their production process.

Plastic Decorating in packaging

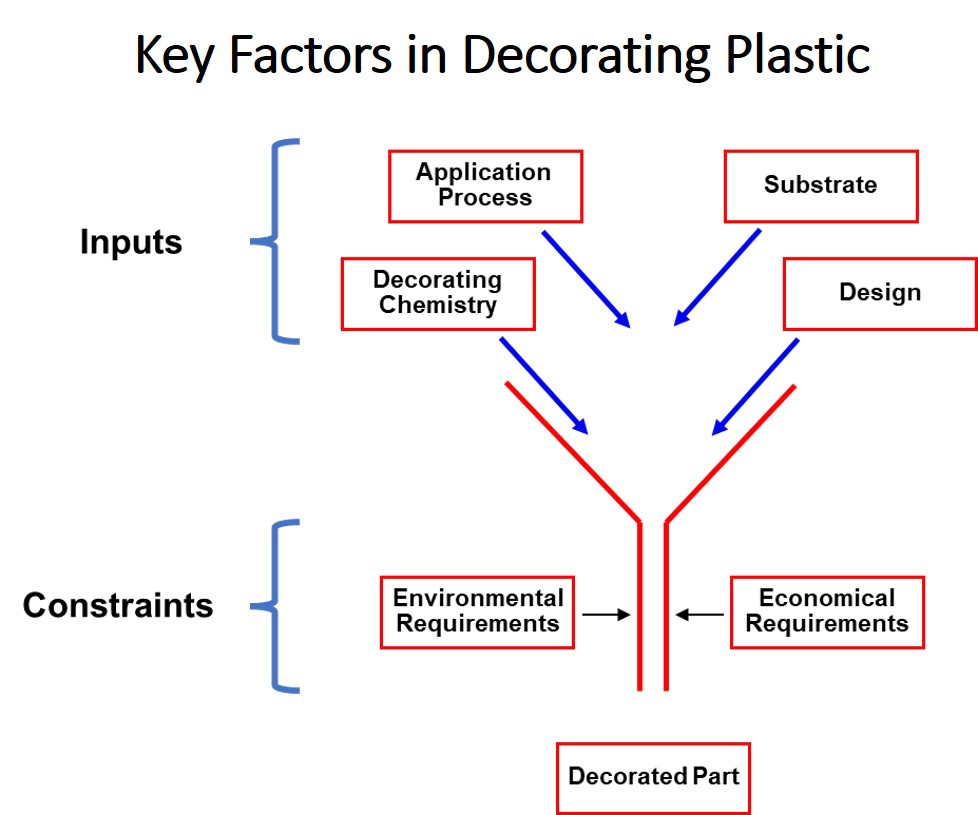

Packaging, by its nature, tends to be a high-volume application for plastic decorating. This lends itself to solutions that use printing processes and high-speed techniques like in-mold labeling. Success in decorated plastic depends upon four inputs: the base plastic being decorated, the part design, the coating or ink applied and finally, the application process. These in turn are constrained by the product requirements, regulations and economics, which include supply concerns and production volume influences.

For packaging, all of these are important. Most decorating processes for packaging involve printing at one step or another. The printing can be directly to the part or to film that is incorporated into the packaging or applied in some way to the surface. No one printing or coating option works best in all applications or is the optimum in meeting all current and future market needs (Figure 1).

Despite its wide use and advantages, packaging has become an environmental and economic issue. Disposable packaging is used because it meets many functional and social needs, yet at the same time, the question becomes what consumers do with it after the use is over. Currently, too much of it ends up in landfills. Consumer perceptions, sustainability and regulatory issues are driving changes in the material, design and process choices.

Plastic packaging has become addictive because of its effectiveness and low cost in meeting market requirements. Decorated plastic packaging meets these needs better than the alternatives, such as paper and glass packaging. Changes in design, process and materials are addressing the circular economy and are a critical part of the future for decorated plastic packaging.

Options to Improve the Environmental Impact

There are numerous responses to the environmental issues, real and perceived, due to the use of plastics. One option is to replace plastics with alternative materials. For packaging, this often is paper or glass. In many instances, paper does not provide the necessary performance requirements that make plastic a good choice in the first place. Glass, although it creates a good package, is heavy and adds to transportation costs. The best solution, often, is to use plastic packaging and reduce its environmental impact.

In looking at alternative options, it is important to understand all of the performance requirements and consider the unintended consequences of change. Not packaging, but a good example, is the replacement of plastic straws with paper straws. The paper ones just do not work as well, often are packaged in plastic and recent studies show many contain forever chemicals like PFAS (per- and polyfluoroalkyl substances). The intentions were good, but the result was disappointing. Care should be taken in elevating changes to improve recyclability so that there are no unanticipated results.

The global demand for sustainable, efficient and innovative packaging solutions continues to grow. Changes in the form of design choices, material choices and ink and coating formulations are the future of decorated packaging.

Plastics

A number of strategies are being employed to reduce environmental impact, comply with regulations and improve the recyclability of decorated plastic packaging. One of the most important is to use the same or similar resins in the finished package. This, together with using a minimum amount of ink, inks that are compatible with recycling or inks that easily can be removed, significantly improves the opportunity to recycle the package.

Another option is to use biobased polymers. The primary issues with them are availability and confirming that they work well with the current inks and processes.

Finally, the use of a percentage of reprocessed or recycled plastics as a part of the product reduces the environmental impact. Although this is a good strategy, care must be taken to ensure the base polymer meets all necessary standards, (food-contact approval, for example,) or other performance-based requirements. One additional concern is that reprocessed or recycled materials, which meet the processing standards, do not always demonstrate consistent performance in coating and printing processes.

Ink

Inks and coatings also are undergoing formulation changes driven by the need to be compatible with new substrates and to support material reduction for less complex packaging structures. They need to be capable of both durable performance on the package and, at the same time, either being strippable or structured so that they do not significantly impact the recycling process. From the ink market side, water-based, low-VOC formulations and UV-curable inks are all viewed as more environmentally friendly than the traditional solvent-based options.

Regulations are driving increased demand for low-migration inks for food and pharmaceutical packaging, as well as PVC-free NC-(Nitrocellulose) free and solvent-free inks. Nitrocellulose-free ink systems are needed to support flexible packaging recycling, as required in European recycling standards. Innovations include the use of graphene to make recyclable conductive inks and the development of soft-feel inks to add tactile performance to packaging products.

Regulations

Keeping up with regulatory compliance is a significant challenge, as global regulations are evolving at a fast pace, so it is imperative to remain up to date and be aware of both current and proposed regulations.

EU Packaging and Packaging Waste Regulations (PPWR) mandate that by 2030, all packaging must be 100% recyclable. The intent is that every component in the value chain fits with the recycling infrastructure. In addition, under PPWR, producers are subjected to Extended Producer Responsibility (EPR) criteria that impose fees based on how easily their product can be recycled.

North America Extended Producer Responsibility (EPR) regulations are being developed state by state, with Oregon’s being the first to take effect. This will no doubt lead to a patchwork of regulations. Regulations like California 343 Truth in Labeling will impact which materials are considered recyclable and establish strict criteria for recycling claims.

Evolving Processes

A variety of processes used in decorated plastic packaging are evolving as well:

Flexographic and gravure

Flexographic and gravure remain the gold standard for printed appearances by providing both high resolution and superior color consistency. Both are suitable for first surface and reverse printing and provide high color strength and high opacity. Both technologies continue to evolve, and techniques such as laser-engraved cylinders improve quality and reduce the risk of print imperfections.

Their strength is the ability to handle the high-volume production runs favored by global brands. They are capable of print speeds of up to 1,000 meters per minute. This also is their weakness; they are less optimal for shorter runs. Both processes work well with new inks designed to meet PPWR standards and can print conductive inks necessary for future smart packaging options.

Digital Printing

Digital printing is well-suited to packaging because of the ability to provide a rapid turnaround. Digital printing also works well for short production runs and allows for more personalized packaging. In short, it provides flexibility and operational efficiency not available with traditional printing methods. As the chemistry and delivery systems continue to advance, digital inks and processing clearly are growing in popularity and in existing and new applications. The strengths of digital print are the ability to handle short runs, provide quick turnarounds and provide variable data printing; the limits, are the print head capabilities and available inks.

In-Mold Labeling

In-mold labeling (IML) and in-mold decorating (IMD) are particularly effective in supporting the circular economy. This is because the printed label is an integral part of the finished package and, if made from the same material, easily is recyclable. The Association of Plastics Recyclers has designated IML as the preferred label method for polypropylene and high-density polyethylene. For recycling, the amount of ink must be less than 1% of the packaging by weight, and dark colors and bleeding inks should be avoided. Using correctly designed IML can reduce the resin use by about 15%.

Silk Screen

For applications with a limited color palette, silk screen printing is very effective. It particularly is well suited to containers that are cylindrical and easily is implemented on small-batch applications or combined with other decorating processes to provide additional value (Figure 2).

Other Processes and Combinations

For applications like prestige cosmetics, metallic appearance still is favored. Processing that includes inline physical vapor deposition, followed by inline UV hard coating, offers a high-quality appearance that either can be a conventional metallic appearance or color-tinted metallic appearance. These can be achieved in either high gloss or matte finishes. Thermal transfers and metallic thermal transfers, although not easily recyclable, remain popular (Figure 3).

As with most plastic decorating, it is possible to combine processes on a single part. Combinations of silk screen printing, hot foil stamping, metallization and lacquering finishes can be combined to produce innovative appearances. New processes, such as Geka’s shadow printing, which produces decorative surfaces that combine high and low gloss as well as textured surfaces, are recyclable. This process also can be combined with foil or printing to enhance the appearance

(Figure 4).

Supply Chain Issues

The impact of recent trade wars and tariffs is yet to be seen. It certainly will have an effect on all plastic decorating materials and plastics. Pigments and ink precursors often cross borders several times before the final product is ready to use in production.

Larger companies are looking to standardize materials and inks across multiple regions. There is a focus on supply chain resilience and the development of materials that comply with regulations while supporting recyclability in all regions.

Conclusion

It is clear that the use of decorated plastic is going to continue to grow and also that the materials, processes and designs will continue to evolve to meet the changing market and new regulations. Understanding both the regulations requirements and what the decorating process capabilities are will be critical to success. The constant evolution of technology and a simultaneous dynamic regulatory environment make choosing the right technology and material set to ensure return on long-term capital investments challenging, but with challenges come opportunities.

References

D. Strickland, Flexography and gravure printing still pack a punch in digital-centric packaging world, Converting Quarterly, 2025 – 1

Christiine Esposito, “Packaging Can be Sustainable & Beautiful,” Beauty Packaging, March 2025

IMDA, “Achieving Packaging Recyclability and Suitability Objective with In-Mold Labeling and In-Mold Decorating”

Paul Uglum has 43 years of experience in various aspects of plastic materials, plastic decoration, joining and failure analysis. He owns Uglum Consulting, LLC, working in the areas of plastic decoration and optical bonding. For more information, send comments and questions to paul.a.uglum@gmail.com.