Costing, designing and developing a robust and repeatable manufacturing process, regardless of the application or industry, is a daunting task. In the plastics industry – specifically injection molding – the challenge can be amplified by tight tolerances for form and fit, meticulous surface finishes, the individual processing characteristics of resins, existing machine capacity, efficiencies and personnel resources. Manufacturing contracts can be years long with specific performance metrics and milestones, penalties for shortfalls and, ultimately, eroding margins. The more involved and broader the project scope, the greater the need for due diligence and careful planning.

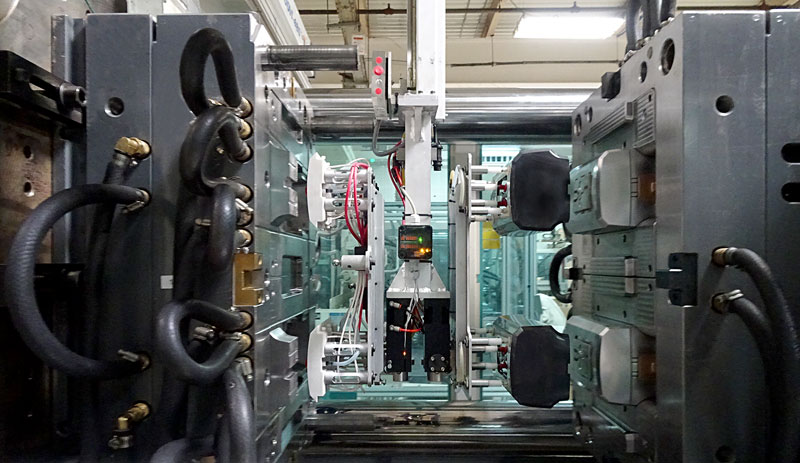

Adding the in-mold decorating aspect to the injection molding process compounds the difficulty matrix. It means adding extra equipment, materials and tight tolerance-based movement to the workflow. With each additional phase of a product manufacturing process comes the potential for additional scrap and equipment down time. Because of these additional variables, a systems engineering management method is critical to an IMD project.

Identifying areas of study

Start by identifying and defining every step in the total process before breaking it into manageable action plans. Rather than simply assuming each person or supplier is responsible for the delivery of their piece, create a platform where the goals of the individual are understood in relation to the goals of the group. The individual components of an IMD project cannot be designed, developed and created in isolation. Every design decision made early on will impact successive phases.

What confirmed or non-negotiable information can be proactively shared among the team? This requires an open and communicative original equipment manufacturer (OEM)/brand owner. Design concessions are inevitable once engineers begin digging. At the tool shop, all the standard considerations are still present: steel selection, gating, cooling and ejection – but these decisions now must account for the presence of the decorative film. At the molder, all the standard considerations are still present: press size, cycle time, materials procurement, part handling and packaging ejection – but these decisions now must account for the presence of the decorative film.

Design for manufacturing (DFM) evaluation is especially important due to surface attributes – both visual and dimensional. Comprehensive process simulation is a valuable tool in forecasting challenges with regard to flatness, hot spots, cooling, flow and more.

Anticipating challenges and devising options

Because of the additional complexity of adding IMD, utilize a failure mode effects analysis (FMEA) approach, individually and collectively. This means building a virtual system by mapping out each phase of design, development (prototype and/or pilot) and production launch. This is obviously done to quote the job – to identify the cost of the injection mold, fixtures, robots, resins, artwork, film, assembly equipment, packaging and required personnel. In addition to their financial impact on the manufacturing cell, examine those individually identified phases and determine if they represent the best approach by asking what can go wrong. This literally means mapping out and questioning every station and workflow progression.

Example One: At the tool shop – Injection mold design characteristics

- Gating location and style – Part geometry may dictate where the part will be gated but the film works best when injection happens as symmetrically central as possible, fanning out from the fill center and holding the film in place during flow activity. Which one gets priority if the locations differ: part or film?

- Cooling strategies – The injection point brings a great deal of heat to the film at specific points of entry, with the potential for damage to the art. Which will be more effective for controlling steel temperature: cooling channels or steel selection? Should induction heating technology be considered?

- Maintaining film placement location – Which method will be best: static charge, vacuum or a locating feature in the steel and part? Or a combination of methods?

Example Two: At the molder – Manufacturing cell characteristics and film handling procedures

- End of arm tooling fixture design – At which touch points should the film be picked up to ensure one-at-a-time capture (per cavity), and what must be done to place it accurately in the mold? Are finished parts being retrieved with the same end of arm tooling (EOAT)?

- Managing label flatness – Which label nest method will be best? How big an impact will the molding environment have on film stability and performance within the process? Temperature, humidity and air cleanliness have a direct and profound impact on film – not just at the injection molding machine but where the films were stored prior to molding.

- How do operators effectively handle the part for any successive value-added operations (assembly, additional decorating, testing, packaging…)?

Qualification of an IMD process

Allowances must be made for the likelihood of significantly more set-up time during sampling and qualification stages. Because of the presence of the film, an IMD sampling event will most assuredly take considerably longer than a traditional mold functional sample. The basic goals of ensuring water circuits are sound, the ejection system functions properly, tool actions and shut-offs behave as expected are still there. However, molders also hope to see the decisions they made in the steel hold true for molded part dimensions.

But IMD brings many new goals and challenges to this stage. Is the film being effectively transported to – and is it staying in – the mold? Is the film maintaining its position during injection? Is the molded and decorated part meeting the aesthetic requirements? When molders are ready to trial the system, they will need to set up their manufacturing cell to an as near-to-production environment as possible.

Depending on the customer and application of the final product, meticulous aesthetics may be required – even during the qualification stage – as these parts often are used as marketing samples. A comprehensive validation phase and a long-term debugging mindset are necessities prior to production launch.

Everyone on the same page and on the same team

It all comes down to hitting the launch window with qualified product and a robust process. Each supplier has a distinct role to play and its own areas of experience and expertise on which to draw. Each supplier also must be a proactive contributing member of the develop-and-launch team.

That means everyone is at the design review table together. It means listening to and understanding the individual challenges of the other members of the supply team. It means looking at a collection of innovative techniques and best practices to potentially eliminate another supplier’s hurdle. Instead of operating exclusively in a silo and concentrating on a specific deliverable, pay careful attention to the other suppliers’ questions and assumptions. Try to see the project from the perspective of the other supply partners.

Because of the nature of the IMD beast, a successful launch requires far more than building to spec. The film supplier can simply print and cut to the exact measurements supplied. The tool shop can design and build the mold to the database and print. The molder can create the production cell environment using the equipment appropriately sized for the scope of the project.

Everyone does their job by the book to the best of their abilities, and everything can get derailed in the first cycle of the first trial: films not separating properly in the staging magazine, films not staying in the open mold after load, injection flow pushing the film out of place, film art discolored by the heat from injection… Molders won’t know what will happen until it happens.

However, if they proactively collaborate well and forecast challenges to each other, they can use their combined experiences and problem-solving skills and have Plans B and C at the ready.

John Berg is the director of marketing for Sussex IM, a custom molder specializing in value-added manufacturing. He has more than 30 years of experience in business-to-business marketing, sales and business development. He has been working in the plastics industry for more than 18 years. Berg serves on the education and marketing boards of the In-Mold Decorating Association. For more information, visit www.sussexim.com.