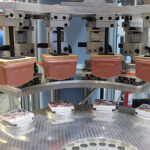

by John Kaverman Selling pad printing equipment on a daily basis has perpetuated many unusual questions. It seems that people today, including those in the pad printing industry, never seem to have enough time to analyze their equipment purchases correctly, but seem to find time to repeat mistakes because they are not using the right equipment for the right job. Many initial … [Read more...] about Making the Right Choice – Pad Printing Machinery

Pad Printing

Open Well versus Sealed Ink Cups

by Staff Over the past several years, the pad printing market has seen a transformation from the use of open ink well systems to sealed ink cup systems. This is especially true in the U.S. marketplace where sealed cup systems have dominated new equipment purchases for the last several years. However, open ink well systems are still very popular throughout the world. Certainly … [Read more...] about Open Well versus Sealed Ink Cups

Decorating Hollow Parts

by Jordan Rotheiser This last June, I had the privilege of moderating a seminar entitled "Decorating Hollow Parts" at the Society of Plastics Engineer's "Hollow Parts Conference" in Chicago. It was sponsored by the Decorating and Assembly Division of the SPE, and presentations were provided by Keith Hillestad (United Silicone), Jodi Laughlin (Pro Mark) and Mark Wille … [Read more...] about Decorating Hollow Parts

Optimal Conditions for Pad Printing

by John Kaverman It is the one question I can depend on getting from every new pad printing equipment customer: "Does it make a difference if I do my printing in a controlled environment?" Yes. Controlling your operating conditions from day to day can make your job significantly easier. Temperature and Relative Humidity It is recommended that, as a minimum, at least the … [Read more...] about Optimal Conditions for Pad Printing

Mixing and Matching Pad Printing Inks

by Jeff Peterson Pad printing inks are a very delicate matter because of the process in which they are used. There is a very tricky balance that must be obtained between the type of application, the speed of the machine, and the drying times of the ink. Every application can be vastly different – meaning the proper mixing and color can change from job to job. We have called … [Read more...] about Mixing and Matching Pad Printing Inks