Edited by Lara Copeland, contributing editor Plastics Decorating SIMPLESTAKE, a subsidiary of ToolTex, located in Grove City, Ohio, developed a new technology to solve issues common with staking methods. “Traditional heat staking is a messy business altogether,” Josh Clark, national sales manager, said. SIMPLESTAKE utilizes impulse staking technology to provide a new level of … [Read more...] about SIMPLESTAKE’s Impulse Staking Technology

Staking

Staking by Ultrasound – Strong Joints in Short Cycle Times

by Thomas Fischer, head of application development, Herrmann Ultraschalltechnik GmbH & Co. KG; Eric Brückner, Institute of Conveyor Technology and Plastics (IFK); Dr. Michael Gehde, head chair for plastics, IFK A novel version of ultrasonic staking for joining plastics and dissimilar materials utilizes a tubular rivet that it shapes into a form-fitting bead. This new … [Read more...] about Staking by Ultrasound – Strong Joints in Short Cycle Times

The InfraStake Process – Seeing the Light

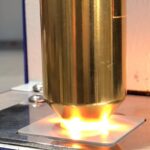

by Scott Beute, Extol, Inc. The practice of forming a molded stud or boss in order to retain another component is nothing new. Long ago, engineers recognized the benefits of eliminating glue, screws, and other fasteners, and as a result, they developed several different methods of heat staking that have been around for quite some time. Against this backdrop, a nonconventional … [Read more...] about The InfraStake Process – Seeing the Light

Staking & Insertion – Why Heat is the Better Choice

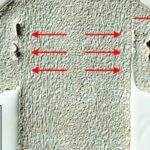

by Michael J. Brunetti Back in the mid- to late 1960s, most molders and product designers thought that heat insertion and even heat staking were non-repeatable, unreliable or inconsistent methods of installing metal inserts into plastic or staking over of plastic posts. This was due to a few factors. First, ultrasonic technology was sweeping the country – billed as a "fix all" … [Read more...] about Staking & Insertion – Why Heat is the Better Choice

Heatstaking in a Nutshell

by Eric Gregorich, Plastic Assembly Systems Approximately 15 years ago, a more complex and versatile process evolved in secondary molding technologies. Many of the existing processes (ultrasonics, RF welding, hot air cold upset, impulse, infrared, hot plate welding, and vibration welding) were limited, and manufacturers in secondary assembly needed a process that would … [Read more...] about Heatstaking in a Nutshell