by Dave Clothier, FRIMO, Inc. For several years, the process of infrared (IR) welding has been gaining importance in the thermoplastics industry as a competitive alternative to classic joining techniques used in high-quality thermoplastic manufacturing processes, such as vibration and hot plate welding. Method and benefits IR welding is a non-contact joining method that, … [Read more...] about Advantages of Infrared Welding in Thermoplastics Manufacturing

Welding

Advantages of a Servo-Driven Ultrasonic Welder

Ultrasonic welding is one of the most widely used processes for bonding polymers, valued for its speed, flexibility and low cost. Recently, there has been a call for more controlled and consistent ultrasonic welding processes, as part designs become more complex and requirements more stringent. There also is a need for strong, dimensionally consistent parts that show good … [Read more...] about Advantages of a Servo-Driven Ultrasonic Welder

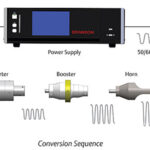

Optimizing Ultrasonic Welding Results

by Jeffrey Frantz, Branson Ultrasonics Corp. Ultrasonic welding is a technology that has been used for decades to assemble plastic components. There are many benefits of this technology. It allows for plastic parts to be assembled without consumables. This not only eliminates the cost of the consumable (such as screws or rivets), but in the case of adhesives and solvents, … [Read more...] about Optimizing Ultrasonic Welding Results

Progress in Lasers Improves Polymer Joining

by Tony Hoult, IPG Photonics Lasers still are often perceived as exotic energy sources, but the rapid emergence of a new type of highly cost-effective laser – the fiber laser –gradually may change this. We will define fiber laser technology as the technology where the laser beam is generated or amplified actually within a fiber optic component itself, rather than simply … [Read more...] about Progress in Lasers Improves Polymer Joining

Ultrasonic Welding: The Need for Speed Control

by Tom Kirkland, Tributek A couple of years ago, demonstrations were set up at a seminar on ultrasonic plastics welding to illustrate the effects of contamination and energy director damage on an ultrasonic weld and to demonstrate the capability of a particular piece of equipment to detect that something went wrong. The first demonstration, set up prior to the seminar, was … [Read more...] about Ultrasonic Welding: The Need for Speed Control