by Brittany Willes, editor, Plastics Decorating

In a world that is constantly upgrading to the latest technologies, the old saying “out with the old, in with the new” has never seemed so relevant. However, as many in the plastics decorating industry can attest, the newest technology or process is not always the best choice when it comes to specific applications. Pad printing technology is certainly not new, and while processes like inkjet are taking on some roles previously filled by pad printing, that doesn’t mean the older process has become obsolete by any means. Pad printing has – and likely always will have – a very important role to play when it comes to decorating plastic applications.

Limitations and benefits

There is no denying that pad printing (like all processes) has its limitations. One of the biggest is when it comes to color printing with multiple solid colors. For example, “If the printed image is a solid rose using all red colors, it will be difficult to actually print that solid color very clearly with a smooth tone image using pad printing,” remarked Engineered Printing Solutions President of Commercial Services Julian Joffe. “For situations like that it is better to screen print.”

Furthermore, pad printing is not well suited for applications that require variable data, as explained by Pad Print Pros President John Kaverman. “Since a cliché (printing plate) must be made for each unique image, it is not cost effective to print serial numbers or ‘each one’ codes, names, etc.,” he stated.

Given the push to incorporate more robotics and automation into production processes, it might be tempting to think that automation would allow pad printing to be more cost effective when it comes to part variety. However, this is not necessarily the case, as Kaverman explained.

“Typically, people don’t understand that a fully automated system is dedicated to a part, or a specific family of parts, having similar geometries,” Kaverman stated. “They think you can build an ‘automation’ to do a dozen or more completely different part geometries; and we can, but it becomes substantially more expensive when we employ camera systems and multiple axis robots capable of picking up a specific part from a variety of parts, orienting it as required and loading it to the system.”

Thus, while pad printing is great for mass production of products bearing the same image, producing large quantities of truly customized, one-of-a-kind products is not a realistic option. In that situation, something like inkjet again becomes the better option.

Despite its limitations, pad printing is still a solid platform and it does have its own advantages over other processes. For instance, when it comes to printing smaller, high-resolution images, pad printing still has an edge over other processes such as inkjet.

“Whether printing smaller monochrome or even multicolor images, pad printing will produce a beautiful image,” said Joffe, “whereas other processes tend to be a little less quality-focused. Even something like offset or screen printing will not necessarily render the same quality that pad printing will.”

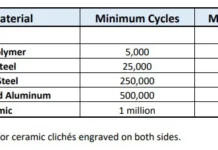

There are other issues beyond image quality to consider as well. While a process such as screen printing is capable of performing some of the same functions as pad printing, that doesn’t necessarily make it the better option. As Joffe explained, “Screen printing turnkey has an open screen, so unless UV inks are being used, screen printing with a solvent-based ink becomes problematic. The screens don’t last as long; they tend to become damaged after 2,000-3,000 cycles. Also, the ink viscosity changes dramatically over time. Pad printing doesn’t have these kinds of issues.” In terms of reliability, consistency and ease of set up, pad printing is one of the best processes available, he stated.

Complexity is the key

“Pad printing can provide superior color spot reproduction and image resolution compared to most other decorating process,” said Kaverman. “Especially where more complex part geometries are involved.”

The ability to print on unusual and complex shapes is perhaps the area where pad printing shines the most. From golf balls to automotive switches to light bulbs to colonoscopy tubes, pad printing is the go-to process for high-quality images, whereas something like inkjet does not lend itself well to complex shapes.

The automotive industry in particular relies heavily on pad printing rather than inkjet. “For automotive producers doing any kind of decorating, pad printing is essential for keeping their customers happy,” remarked Joffe. “The surface can be a little rough and you can still get a very high-quality image. For many of those applications that are curved or concave, the quality is just not there with inkjet.”

For products like golf balls that are curved with indentations, achieving a quality print with inkjet is nearly impossible. Due to the nature of the process, accuracy is lost and image resolution suffers. Furthermore, when it comes to monochrome products – whether oddly shaped or not – pad printing will likely be the more efficient and cost-effective solution.

Looking ahead

When it comes to the sale of pad printing systems, Joffe and EPS have been keeping close tabs on which systems are the most in demand. Overall, the sale of smaller, single-color systems has been in decline in recent years. Despite this, EPS’ sales revenue has continued to climb due to the increased demand for more sophisticated, multicolor machines.

“While inkjet has been eating into some of the pad printing market share, pad printing is certainly not declining,” said Joffe. “We’ve been watching pad printing sales very carefully since 2014 to gauge trends, and revenue continues to go up each year. Pad printing is here to stay. There’s no doubt about that.”

Joffe is not the only one noticing some distinct trends emerging in the pad printing market. Kaverman noted: “We have been doing a lot more applications where we are transferring functional materials – conductive and dielectric inks, radio-opaque materials, adhesives and lubricants. We’ve also been integrating more systems with flexible feed systems (vison-guided robots) and vision inspection systems.”

Thus, while full automation is not yet realistic for most pad printing systems, there are areas where it is being utilized more and more as the technology becomes more sophisticated. This should come as no surprise. Automation, like pad printing, is here to stay.

“There is always going to be a demand for pad printing,” said Joffe. “Particularly when it comes to mass production of monochrome products or products that are oddly shaped.”

Even as processes like screen printing or inkjet compete for market share, there is no doubt that pad printing will always have a place in the industry.