How interesting is the small-format digital printing market? This is a growing sector of an undefined area of the market. These printers have been specifically designed to accommodate printing on flat or three-dimensional products. Most of these printers use UV inks, which will adhere to a variety of substrates, giving the user versatility in applications and a low-cost way to break into high-value, niche markets like the printing of cellphone cases or similar products.

How do we define this market?

For now, perhaps the best fit for small-format digital printers is promotional products. Advertising Specialty Institute reported promotional product sales in 2014 reached a record-breaking $21.5 billion, increasing by five percent over 2013, with continued growth expected. Although the “promotional products” industry is wide and includes applications like apparel (which is not the focus of small-format digital printers), the margins for printed products are usually 50 to 100 percent compared to printing collateral, which falls in the 10 to 30 percent margin range.

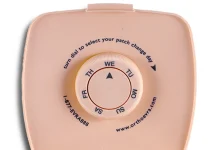

This is a big market, and versatility is key. The ability to offer your customer a variety of products – such as pens, key chains, luggage tags, golf balls, etc. – with high-quality printing, low minimum quantities and quick turns is essential. Even as most promotional goods tend to be printed in China, more and more products are being produced (or requested to be produced) in the US, as lead times do not allow for shipping/transportation from out of the country, and consumers are driving the trend of “Made in America.”

Types of applications

Because UV inks adhere to a variety of substrates, small-format digital printers are printing almost any application the user can think of – tablet cases, photo frames, awards, leather wristlets, belt buckles, etc. These printers also can print non-3D items, such as photo books. The inkjet printer can print on a variety of substrates, including thinner substrates that may have melted during curing of other printing processes. The versatility in applications is a key consideration in the user’s purchase decision.

How were these applications being produced before?

For the most part, small-format digital printing machines have found a new market especially when variable data or variable graphics may be involved with decorating the product. These printers perfectly fill a need for low- to mid-range quantities of high-quality printed products. These applications weren’t being efficiently produced or produced at all before because screen printing was too costly at lower volumes. Pad printing was used in many of these applications; however, digital printing opens more opportunities for 4-color process.

Dye-sublimation transfer printing still is a technology used to produce some of the same products as the small-format inkjet printers. However, multiple steps are associated with dyesub transfer and, again, it is not ideal for very short runs. Laser engraving/etching is popular for metal and glass objects, but it does not allow for color graphics, and it will work on limited substrates.

Market sizing

Many locations are installing additional printers, which means business is good for these users. As the market grows and with more competition, sell price may decline. However, margins for products produced often are 10 times the cost to produce. The ROI on hardware is achieved quickly and justifies the purchase. As discussed earlier, these printers are being installed in a variety of situations – not just at print businesses.

Bottom line

Customization is king for these small-format digital printers. Yes, some may think of this as “only a niche market,” but isn’t this “the target” of most new-to-market digital printers? Perhaps, in the future, these machines will become faster and bigger, allowing them to handle more volume and begin to replace larger volume printing. Or will these printers continue to fill a niche at the low-volume end of the market and for sampling? Although this platform may not ever replace printing methods for higher quantities, it will allow for custom branding for smaller businesses without a need or budget for mass production.

These printers fill a need for high-quality printing of low-volume objects while eliminating traditional setup costs (or multi-step applications as with dye-sublimation transfer printing) as well as increasing turn times. Printing on demand allows product delivery to the customer much faster than product produced overseas by eliminating long shipping times and high costs.

At any rate, the output is in demand and provides a nice margin for the user. The low cost to acquire and compact footprint make this an attractable option for users looking to diversify their offerings or expand into a new niche market – or for a brand that wants to build a business around a specific product.

Explore the latest industrial print solutions for functional, decorative and package printing when InPrint USA makes its debut in Orlando from April 25-27, 2017, at the Orange County Convention Center. Co-located with ICE USA (the International Converting Exhibition), InPrint USA will showcase an array of print technologies – from screen and specialty to digital, inkjet and 3D. For more information or to register, visit www.inprintshow.com/usa.