by Paul Uglum, president, Uglum Consulting, LLC

Plastic parts are decorated for many reasons and using many differing techniques. Parts can be decorated to achieve specific aesthetics and appearances, to provide uniform appearances across various substrates, to apply graphics and to achieve specific functional or tactile results. Coatings also are applied to protect the substrates from one or more failure modes and to increase the durability of the part. Understandably, it is disappointing to then experience field failures of the coating or of the part as a whole.

Failures can be formula-related, design-related, substrate-related and/or process-related. Because of this, great care is taken in the development, selection and testing of plastic decoration to ensure the products will meet all of the expectations, including long life without failure. Even with all of the preparation and testing, unexpected field failures can occur.

Entire books have been written about the testing of decorated plastics and the analysis of failures. One of the significant causes of failures is exposure to various chemicals in the environment. These occur on purpose – with cleaning, by accident – with spills and inadvertently – by the transfer of personal care products during the handling and operation of the product.

The susceptibility of specific decoration chemistries, quantity of exposure, length of exposure and surrounding environmental conditions all have some impact on the outcome. All of these are considered in the design and development of products, so it is worth looking at why this effort sometimes fails to ensure durability in the field.

Failures can result from single overstress conditions that exceed the ability of the decoration to resist that stress. They also can occur from cumulative damage as a result of multiple exposures over time. In addition to the primary active components in commercial disinfecting and personal care products, it is common for the products to contain a complex mixture of additional chemicals. Unfortunately, these mixtures can be much more aggressive to plastic decoration and plastics than just the primary active components. These additives attack the surface, hold the active chemicals on the surface and often enable them to better penetrate the coating.

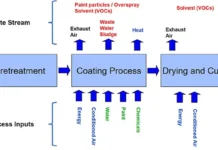

Since this is an environmental stress, any surface exposed to contact with the chemical stress is at risk. In its simplest form, decorated plastic consists of a plastic substrate with one layer of applied material on the plastic. Many forms of decoration are multi-layered, and interlayer adhesion and effects also must be considered. In the case of coatings, it is worth understanding what effects chemical exposure can have on the coating. There are several potential outcomes of chemical exposure. Ideally there is no noticeable change in the decoration or its performance. Unfortunately, a number of undesirable outcomes can occur.

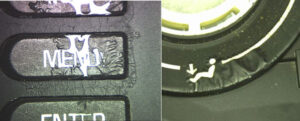

The most common damage is softening, which makes the decoration more susceptible to physical damage or swelling with the potential of delamination with bubbling or wrinkling of the coating. The damage can be relatively mild and reversable when the chemical evaporates. Unpublished studies show that even when the apparent exposure is reversable, there can be a significant reduction in the adhesive strength of the bond between the coating and the substrate. Some chemicals can penetrate the coating without visibly damaging the coating and attack the substrate below either by stress relieving the plastic or by causing chain scission or swelling. Chemical exposure can infrequently cause the coating to become embrittled or friable with or without adhesion failures.

Two of the drivers for unanticipated chemical exposure are people’s changing behaviors, based on real or perceived risk, and innovations in products that result in the introduction of new chemicals or collection of chemicals into the environment. Both are currently occurring in three significant areas: cleaning, sanitizing and disinfecting surfaces due to the coronavirus; sunscreens formulated to prevent skin cancer; and insect repellents formulated to prevent various insect-borne diseases.

Cleaning, sanitizing and disinfecting

The COVID-19 pandemic, along with surrounding governmental recommendation and extensive press coverage, has resulted in a significant increase in both the frequency and the variety of cleaning and disinfecting. This is a significant change in behavior and can be expected to increase the failures for decorated surfaces that are not sufficiently robust.

Most of the contact is direct exposure from sprays and wipes. As with any commercial product there are many and varied active ingredients. Typical active ingredients include ethanol, isopropanol, quaternary ammonium, citric acid, phenol and others. A typical wipe has many components, beyond alkyl dimethyl benzyl ammonium chloride and ethanol, there are stabilizers and fragrances, so 10 chemicals can be expected in any given formulation. Sprays can easily contain up to 18 chemicals. Labels can be helpful in understanding just what is in any given formulation.

With hand sanitizers, exposure is due to handling transfer. The World Health Organization recommends 80% ethanol or 75% isopropanol for hand cleaners. Looking at one typical hand sanitizer’s ingredient list shows 12 chemicals. Since hand sanitizers tend to dry skin, many formulas include various moisturizers. The Environmental Protection Agency lists approved disinfectants for use against COVID-19, which is searchable or can be downloaded as a PDF.

Many of these may not be appropriate for decorated surfaces, but it will give a useful reference as to what is available and may be used. In addition to those that are safe and effective, the EPA also provides lists of those that are ineffective or dangerous. Over 203 formulations have been found to contain methanol at levels up to 80% and should be avoided.

It is reasonable to expect that a variety of approved and unapproved products will be used to clean and disinfect surfaces and that, in some cases, this will lead to damage of the decorated surface or the underlying substrate.

Finally, there is some interest in surface disinfectants than provide a residual ongoing protection. The EPA has granted limited approval to airlines to a product containing a quaternary ammonium organosilane compound that binds to the surface, thereby producing a residual disinfection activity.

Insect repellents (and insecticides)

Diseases from infected mosquitoes, ticks and fleas have tripled in the past 15 years. It was not too long ago that Zika, a mosquito-borne disease that causes birth defects, received significant public attention. Tick-borne diseases also have been problematic. Lyme is the best known, but many others – including alpha-gal syndrome, which causes an allergic reaction to red meat – are increasing as well. With the rise in insect-borne diseases, there is increased use of repellents and insecticides.

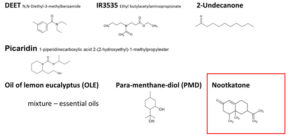

Surface exposure to insect repellents usually results from transfer from handling or from overspray. Unfortunately, the chemical structure of the various approved repellents differs significantly, so each must be tested. A study of the impact of approved insect repellants found that DEET is currently the most damaging to plastic decoration and to plastics, but some other formulations contain up to 12 compounds – these also can be damaging to plastics.

Insect repellents are regulated by the EPA. One newly approved repellent is nootkatone, a chemical found in cedar trees. It needs to be assessed to determine its impact on plastics. It has not been commercialized yet, but testing seems to indicate it is more effective than DEET, so it likely will see significant use at some point.

Sunscreens

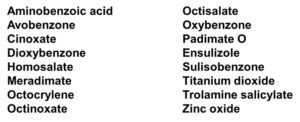

Sunscreens, important in the prevention of skin cancer, are included because they remain a very dynamic area with a high rate of change in formulations. In the US, sunscreen is classified as a drug and controlled by the FDA. As a result, approval has been slow, and Europe is leading the way with the introduction of new formulations. The primary components vary between countries, as does the percentage allowed. Tinosorb S, bemotrizinol, is very popular in Europe but not approved in the US. The good news is that the chemical structures of the active UV absorbers are similar, and that exposure again results primarily for handling transfer or inadvertent spilling or overspray (Figure 5).

Octinoxate and Oxybenzone are common UV absorbers but are now banned in Hawaii, Key West and other locations because of damage to coral reefs and the potential to affect fish. Oxybenzone and other active UV absorbers were approved before it was found they absorbed into the skin and can linger in the body for many days. This has resulted in increased study to find potentially safer formulations. The move toward physical sunscreens, such as zinc oxide, still requires a complex chemical mix, including dispersants and emollients to formulate effective sunscreens.

Strategies for testing range from testing using the active UV agents only, having a set commercial blend manufactured and sold as a standard, or testing with a specific manufacturer’s product at a given SPF level. Each has some limits. Using only the active agents misses the effect of other components. Using a set blend provides uniformity in testing but needs to be reviewed frequently to ensure it is up to date. Finally, choosing a set manufacturer’s product gives a potentially inconsistent stress since the formulation changes over time; this year’s formulation may not be the same as last year’s. Because the formulas and approvals are so dynamic, it is important to keep a close watch on just what is being commercialized.

The next potential damage vector is anti-aging products. A recent survey found that 62% of Americans use anti-aging products as a part of their daily skin care while only 11% use sunscreen daily.

What can be done to minimize risk?

First of all, be informed and aware of trends that drive behavior, as well as knowledgeable about advances in products parts may encounter in the field. It is important to know what is new and what products are in the process of changing. Knowing what is in the most probable products with which the surface will come into contact is not easy. With over 70,000 personal care products on the market, there are a wide range of formulations in the field. Do not rely on safety data sheets alone, since they focus only on materials considered hazardous and how to handle them. Some chemicals considered safe for humans are not so safe for plastics or paints. It is often better to look at labels and follow groups and organizations that formulate or analyze consumer products.

For example, look at groups like the Environmental Working Group, an advocacy group that does significant work identifying the contents of commercial products and identifying which components may be of risk to consumers. Trade journals from cosmetics and toiletries, personal care magazines, household and the personal products industry (HAPPI) all provide information on what chemicals are being used and why.

Actively seek out damaged parts and analyze returned parts to understand the mechanisms and causes of damage occurring in the field. First, visually examine the part to determine the nature of the failure and then use analytical methods such as IR, head space gas chromatography with SIMS to identify the potential cause of the damage.

Make sure testing matches the real-world risk. Don’t just look at the active agents – look at the entire product to which the decoration is likely to be exposed. Synergistic effects can be significant. Consider the frequency of exposure and select the most aggressive member of the family of formulas to use in testing.

In general, if it can be done without compromising other requirements, highly cross-linked coatings with low surface energy are the best to provide enhanced chemical resistance and reduced exposure. Designs should be selected to prevent penetration of solvents beyond the protected surface and to make them easy to clean and to prevent pooling of any potentially damaging solvent on the surface of the parts.

Don’t be afraid to change when field results and testing indicate that a change to a more robust solution is needed. Understanding the risks but making no decision is a decision and can lead to substantial warranty costs.

Paul Uglum has 43 years’ experience in various aspects of plastic materials, plastic decoration, joining and failure analysis. He owns Uglum Consulting, LLC, working in the areas of plastic decoration and optical bonding. For more information, send comments and questions to [email protected].

Paul Uglum has 43 years’ experience in various aspects of plastic materials, plastic decoration, joining and failure analysis. He owns Uglum Consulting, LLC, working in the areas of plastic decoration and optical bonding. For more information, send comments and questions to [email protected].