by Priyank Kishor, global product manager for non-ultrasonics, assembly technologies at Emerson

There has always been a romance with the aesthetic of manufactured products, of items that are thoughtfully designed, beautifully assembled, and elegant in their function and operation. Experienced consumers with an eye for such beauty might point to a piece of ceramics, an upholstered chair, a precision tool or instrument, or the fit and finish of a classic car.

For budget-conscious but tech-savvy younger consumers, the experience and value of beautiful design may differ somewhat, having to compete with price and practicality, but they are nevertheless present. For these consumers, a more subtle form of beauty may be seen in the compact design of a laptop computer, the elegance and reliability of an operating system, the crisp color and response of a touchscreen, or the way that the trim lines of one cellphone allow it to fit far more easily into the hand, purse or pocket than other cellphones.

And so, it is that every designer and every manufacturer must strive to inject a sense of thoughtful design and authentic craftsmanship into the assembly of every product. This aesthetic is even more important for mass-produced products crafted with plastic parts. Plastics struggle to achieve the cachet associated with products made of more traditional materials, but they offer the benefits of light weight, lower cost, consistent strength and almost unlimited design flexibility in terms of part size, shape and color.

There is no lack of assembly technology available for products that rely on plastic parts. Along with fasteners, adhesives and snap-fits, there are a range of friction-based joining methods – ultrasonic, vibration, spin and hot-plate welding. And for any particular product, each method may offer certain advantages that fit with the design and manufacturing capabilities, the size and output of the production run, and the degree of labor versus automation that the assembly process must achieve.

But a growing range of high-end applications – in electronics, automotive, business and medicine – demand not only efficiency but also a higher level of aesthetics in assembly quality and cleanliness. This is where the unique qualities of laser welding fit in for a growing number of manufacturing operations.

Assembly technology to meet a higher standard

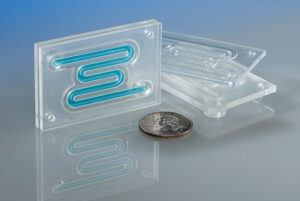

Laser welding is a gentle and ultra-clean joining process that enables welding of plastic parts with complex geometries and wide-ranging materials that are difficult or impossible to bond with other techniques. This process blends high production rates with maximum aesthetics: It can ensure attractive, reliable hermetic sealing in a single step that only takes a few seconds. It also is a process that is as much at home in a cleanroom production area as it is on a busy manufacturing floor.

Laser welding is not always the first plastic joining solution that manufacturers consider. But those who find they need it rapidly learn that it is remarkably versatile and well suited to demanding and aesthetically critical applications. It can join a broader range of polymer materials than friction-based joining processes like ultrasonic welding. And its ability to deliver precisely aligned parts with almost invisible weld joints is unsurpassed by any plastic joining technology.

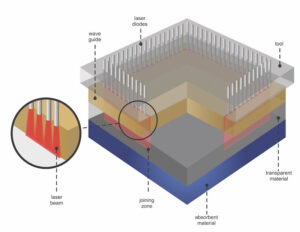

The process itself is simple: Laser welding uses heat provided by a 980-nanometer laser light source, generated by laser diodes. This light is concentrated through fiber-optic bundles connected to the weld tooling, then precisely aimed through waveguides over the weld area of the parts according to the heating density required.

A new process – patented Simultaneous Through-Transmission Infrared® (STTIr®) laser welding technology – developed. The STTIr process differs from other laser technologies, such as track and trace, because it heats the entire weld surface at once.

This process – the same one used by many medical manufacturers to produce microfluidic and drug-delivery products – ensures precise heating and reduces the clamping force required for assembly. Resulting welds are highly precise, with such narrow “collapse depth” between part surfaces that the welds can be made virtually invisible.

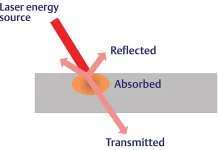

Laser welding joins a much wider array of materials than ultrasonic welding and other friction-based welding methods. Traditionally, it has had only two part design requirements: First, every assembly must have one part whose material is transmissive or clear to the laser wavelength used, while the mating part material is absorbent or black to that wavelength (Figure 1). Second, the part geometry and stack-up must allow passage of laser energy through the transmissive part to the weld zone, where the melt occurs in the upper section of the absorbent part.

Meeting these design requirements is not difficult. There are many transmissive plastic materials, including colorized materials, that readily transmit laser light even though they seem opaque. The same holds true for absorbent parts. Beyond carbon black, a range of color pigments absorb laser light. To be sure the combination of part colors and pigments works properly, consult with the weld equipment supplier.

Appeal grows with latest innovations

Technological advances continue to expand the capabilities of the laser welding process. For example, a new variation of laser welding eliminates the need to use transmissive/absorptive parts, making it possible to weld two transmissive, or clear-on-clear, parts. This advanced process combines STTIr® laser welding technology with a laser-absorbing solution that is applied using ultrasonic spray deposition technology.

The key to the new process is to precision-treat the weld interface of one clear part with a biocompatible laser-absorber. The laser-absorber comprises microparticles of pigment dye or carbon black that are suspended in a carrier fluid, such as isopropyl alcohol or acetone. During the welding process, the laser energy hits the absorber and consumes it, releasing heat energy that conducts through the weld zone of both mating parts, which then bond together under compressive force (Figure 2).

A second advance, this time with actuator technology, enables precise positioning and laser welding of extremely small and delicate plastic parts using ultra-low actuation force. Laser welders can be equipped with this new electromechanical actuator, which can control clamping forces as low as 1 Newton.

When combined with the ability of laser welding equipment to precisely aim heat energy, the new actuator’s ability to manage low clamping force simplifies the joining of parts that are extremely small and delicate, complex in geometry, or embedded with electronic components, wiring or sensors. The risk of part deflection, bending, cracking or damage to embedded electronics is virtually eliminated.

Conclusion

Today’s products – whether cars, appliances, computers or wearable devices – demand not only superior design and functionality but also superior execution in assembly to maximize appeal, usability and durability. Already the leader in aesthetics and cleanliness for plastic parts assembly, laser welding technology continues to evolve, providing usability with a wide range of materials and applications.

Priyank Kishor is a global product manager, non-ultrasonics for assembly technologies at Emerson, leading global marketing and product strategy for laser welding and other non-ultrasonic products in the Branson assembly technology portfolio. He has a decade of experience in managing programs and teams involved in global product development and international marketing. For more information, visit www.emerson.com.

Priyank Kishor is a global product manager, non-ultrasonics for assembly technologies at Emerson, leading global marketing and product strategy for laser welding and other non-ultrasonic products in the Branson assembly technology portfolio. He has a decade of experience in managing programs and teams involved in global product development and international marketing. For more information, visit www.emerson.com.

Laser Welding for Plastics Assembly: Beauty More Than Skin Deep

Laser welding offers a range of important benefits to product assembly operations, including:

- Superior aesthetics. Manufacturers increasingly use laser welds for their aesthetics because they are precise and flash-free. Weld lines are virtually invisible.

- Greater part-design freedom. While traditional plastic welding methods often require flat-plane parts, laser-emitting waveguides can conform precisely to complicated part geometry, enabling laser welding of part designs that maximize aesthetic or functional performance. Laser welding also frees designers to employ multiple reflective compartments or to embed sophisticated electronics, sensors or lighting such as organic light-emitting diodes (OLEDs), resulting in more striking, brand-differentiating part designs.

- Excellent weld quality. Laser welds require no friction, vibration or movement. Laser-emitting waveguides can conform precisely to even complex part geometry to ensure rapid and uniform melt across the weld interface. The result is a uniform, consistently strong weld joint with precise melt-collapse depth and perfect part alignment.

- Low mechanical stress. The latest laser welders can manage ultra-low clamp forces, enabling delicate or larger parts to be joined without introducing mechanical stress, so there is no need for part annealing or material stress reduction.

- Ultra cleanliness. Laser welding produces no flash or particulates. It is a cleanroom-capable process that’s equally at home on any production floor.

- Great versatility. Laser welding technology can bond a wide range of polymer materials, including PC, PA, PS, ABS, elastomers (TPU, TPE), PP HDPE, LDPE, PETG, PBT, PPS, PMMA, PEEK, COCs and more.